Advanced Solutions for Temperature Monitoring in Steel Industries

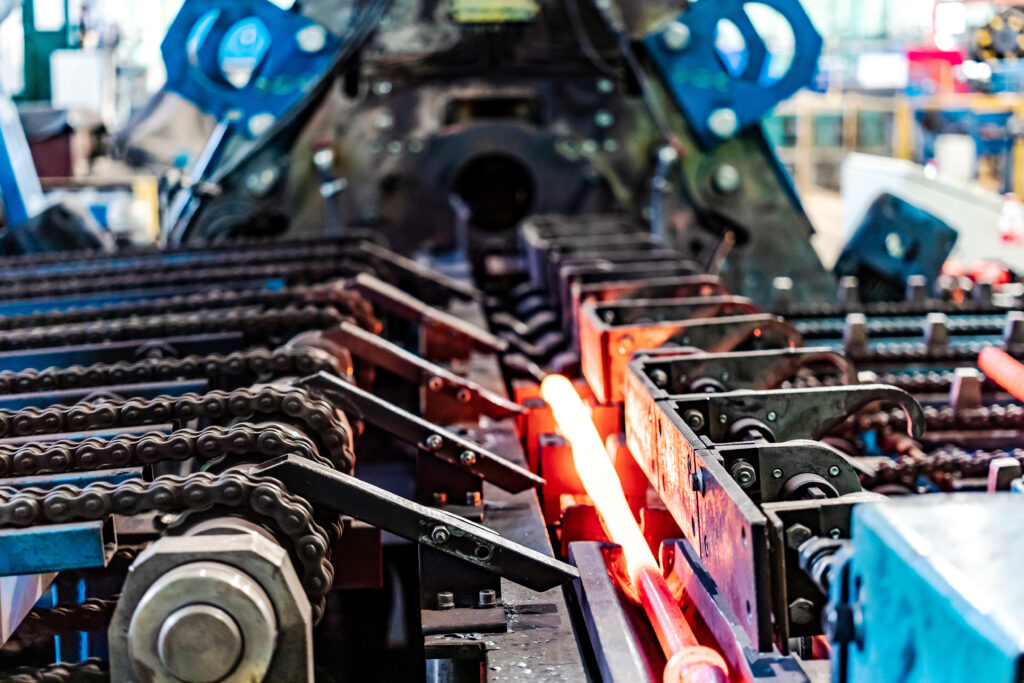

Temperature Monitoring in Steel Industries is vital due to the impact it has on everything from product consistency to energy efficiency. Infrared sensors allow precise, non-contact readings across various stages of steel production, such as molten metal cooling and solidification. These advanced sensors help operators monitor temperature fluctuations in real-time, ensuring optimal cooling rates, reducing defects, and enhancing the overall integrity of the steel. This precision boosts process control, supports quality assurance, and maximizes production efficiency

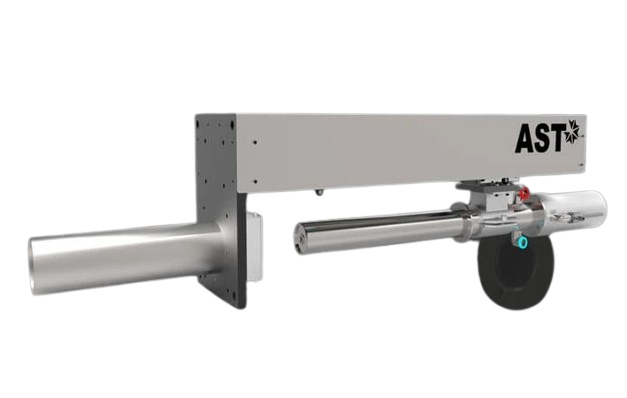

Looking for more industrial infrared pyrometers?

Explore our complete range of Non-Contact Infrared Temperature Sensors for every application

Explore More: Related Technologies & Industry Solutions

Discover Expert Insights in Industrial Steel Temperature Measurement

The Key Benefits of Using an Optical Pyrometer in Industry

Discover the key benefits of optical pyrometers for accurate, non-contact high-temperature measurement in steel, glass, ceramics, and power industries.

Common Challenges When Using Infrared Sensors and How to Overcome Them

Explore the main Challenges When Using Infrared Sensors and how to solve them for accurate, reliable, and long-term temperature measurement.

Infrared Temperature Sensor vs Contact Sensors – Key Differences

Compare infrared temperature sensor vs thermal sensors. Discover how they work, their differences, and why industries rely on AST for precise monitoring.

How Infrared Temperature Sensors Work – A Complete Guide

Discover how infrared temperature sensors work, their benefits, and real-world applications. Learn why industries rely on AST for precise non-contact measurement.

Infrared Temperature Measurement Molten Casting – Guide

Infrared Temperature Measurement in Molten Casting: explore accurate pyrometry for aluminum processes, calibration tips, and real-world use cases.

Designing a Custom Dual-Wavelength Pyrometer for Vacuum Chamber Use

Custom Dual-Wavelength Pyrometer for vacuum and high-temperature applications. Ensure accuracy, stability, and integration with fiber optics and KF40 feedthroughs.