How Infrared Temperature Sensors Work: The Key to Accurate and Efficient Heat Measurement

How Infrared Temperature Sensors Work: these devices have transformed the way industries measure heat. From manufacturing to quality control, they provide instant, contactless readings that improve efficiency and ensure safety. This article explains the science behind infrared temperature sensors, their benefits, and their real-world applications.

Table of Contents

The Science Behind Infrared Temperature Measurement

All objects above absolute zero emit infrared radiation. The hotter the object, the more energy it emits. Infrared temperature sensors detect this radiation using specialized optics and sensors, then process the signal to determine surface temperature. This eliminates the need for direct contact, which is especially useful in high-temperature or hazardous environments.

Advantages of Infrared Temperature Sensors

- Non-Contact Measurement – Ideal for moving objects or surfaces too hot or dangerous to touch.

- Fast Response – Immediate readings keep production lines running efficiently.

- Versatile Applications – Suitable for metals, plastics, glass, food, and more.

- Reduced Wear & Maintenance – No physical contact means longer sensor lifespan.

Industrial Applications

- Steel & Metals – Monitoring casting, rolling, and forging processes.

- Aluminum Extrusion – Ensuring precise billet and profile temperatures to maintain product quality and energy efficiency.

- Glass Manufacturing – Measuring temperature during melting and shaping.

- Plastics – Controlling extrusion and molding temperatures.

- Food Safety – Verifying cooking and cooling processes without contamination risk.

Learn More About Temperature Sensor Applications in Industrial Processes and Manufacturing

AST’s Expertise

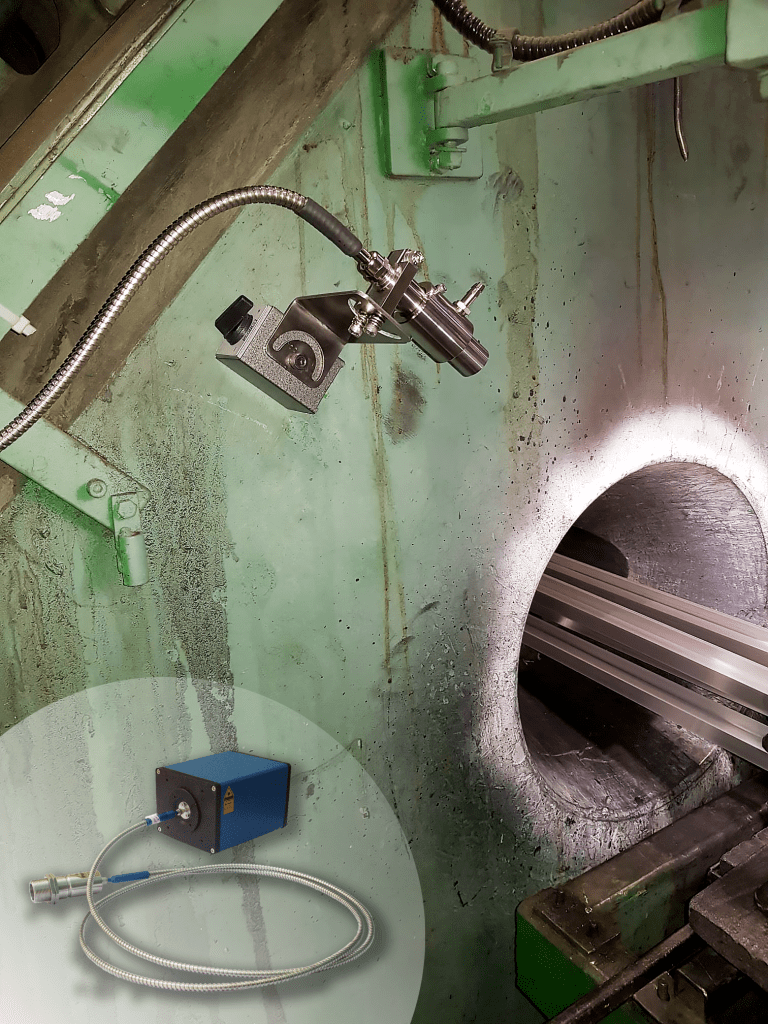

At Accurate Sensors Technologies, we produce a wide range of infrared temperature sensors tailored to each industry’s requirements. Our designs ensure accuracy even in dusty, smoky, or high-vibration environments. Understanding how infrared temperature sensors work helps industries choose

the right solution for their needs.

Want to learn more about our solutions? Explore our infrared temperature sensors:

Explore More Related Content

Frequently Asked Questions About Infrared Temperature Sensors

What is the accuracy of infrared temperature sensors?

Infrared temperature sensors provide high accuracy, often within ±0.5% of the reading, depending on the model and application. Accuracy can also be influenced by the sensor’s optical resolution, target emissivity, and environmental conditions. With proper calibration, they deliver reliable results in demanding industrial environments.

Can infrared temperature sensors work in dusty or smoky environments

Yes. Advanced models are designed to operate in harsh environments that include dust, smoke, or steam. Many infrared pyrometers use filtering optics and protective housings that ensure stable readings even when visibility is reduced. This makes them ideal for industries such as steel, glass, and cement production.

What industries benefit the most from infrared pyrometers

Infrared pyrometers are widely used in steel, aluminum extrusion, glass manufacturing, plastics processing, cement plants, and food production. Any process requiring precise, non-contact temperature measurement can benefit, especially when conditions are too hot, fast-moving, or unsafe for contact sensors.

How do infrared sensors differ from contact thermocouples

Unlike thermocouples, which require physical contact with the object, infrared sensors measure emitted radiation from a distance. This eliminates contamination risk, reduces wear and tear, and allows instant measurement of moving or hazardous targets. Infrared sensors are also better suited for high-speed industrial processes.

Are infrared temperature sensors safe for food applications

Absolutely. Infrared sensors allow hygienic, non-contact temperature verification in cooking, cooling, and storage processes. They ensure compliance with food safety standards by preventing contamination and offering consistent monitoring without disrupting the production line.