Engineering Consultation: Custom Dual-Wavelength Pyrometer for Vacuum Applications

In this guide, we follow up on a real-world engineering consultation involving a dual-wavelength pyrometer project led by Accurate Sensors Technologies’ senior applications expert. The client required a custom solution capable of measuring temperatures up to 2200 °C in a vacuum chamber, with specific installation constraints and optical specifications.

Table of Contents

Why Accurate Temperature Measurement Matters in Vacuum Environments

Vacuum chambers introduce unique challenges for infrared measurement: spectral interference, restricted optical access, and the need for compact, non-intrusive sensor designs. Accurate pyrometer integration is essential for high-temperature applications such as advanced materials research, semiconductor processing, or metallurgy under vacuum—where direct thermal contact is impossible and precise non-contact readings are vital for process stability and product integrity.

Key Requirements from the Client

- Measurement Range: Up to 2200°C

- Technology: Dual-wavelength infrared pyrometer

- Installation: Requires KF40/CF40 vacuum feedthrough

- Focus Size: Between 5 mm and 10 mm

- Sensor Type: Fiber optic configuration

Expert Review and Engineering Considerations

- Optical Installation Configurations

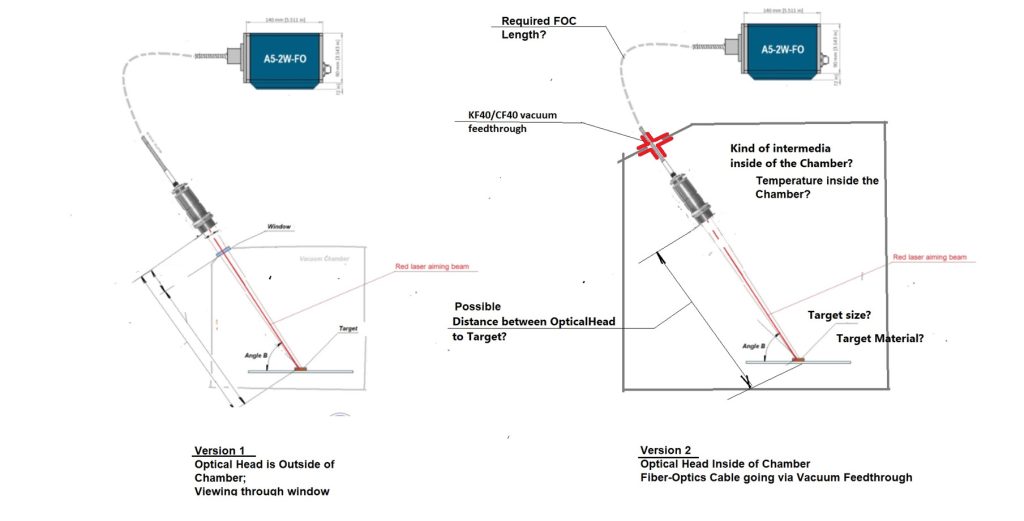

Our application engineer analyzed two possible installation approaches based on the provided chamber layout:

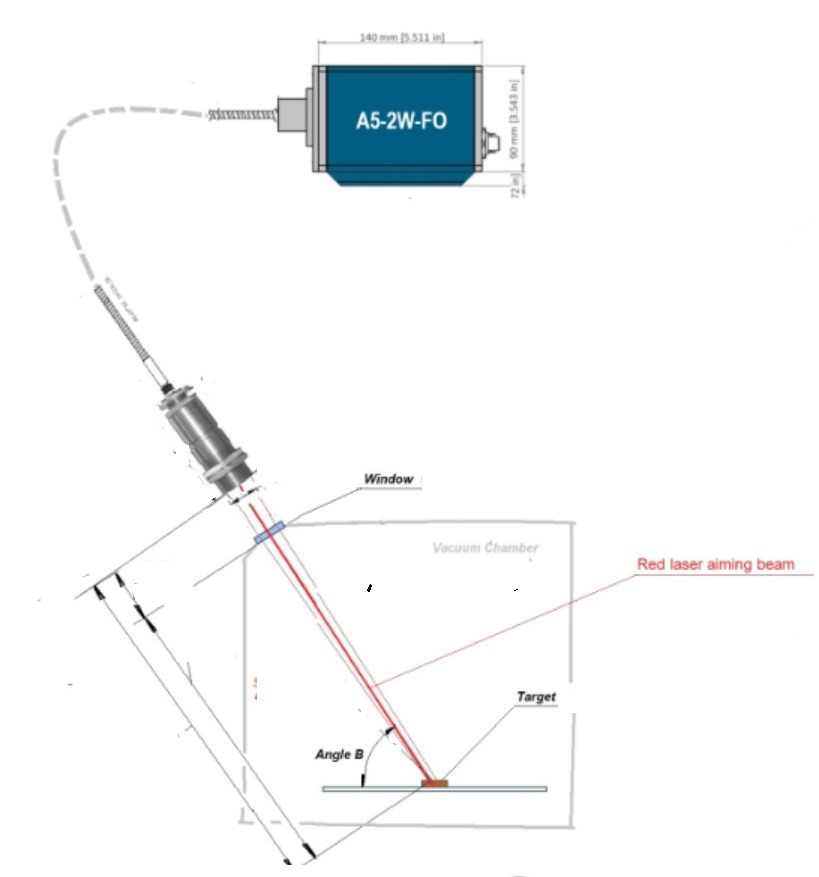

Version 1 – External Optical Head (through a window):

- Pyrometer remains outside the vacuum chambe

- Observes the target via a dedicated infrared-transparent window

- Advantage: Easy maintenance, no vacuum penetration by optical head

- Consideration: Window material must be transparent in the pyrometer’s spectral range

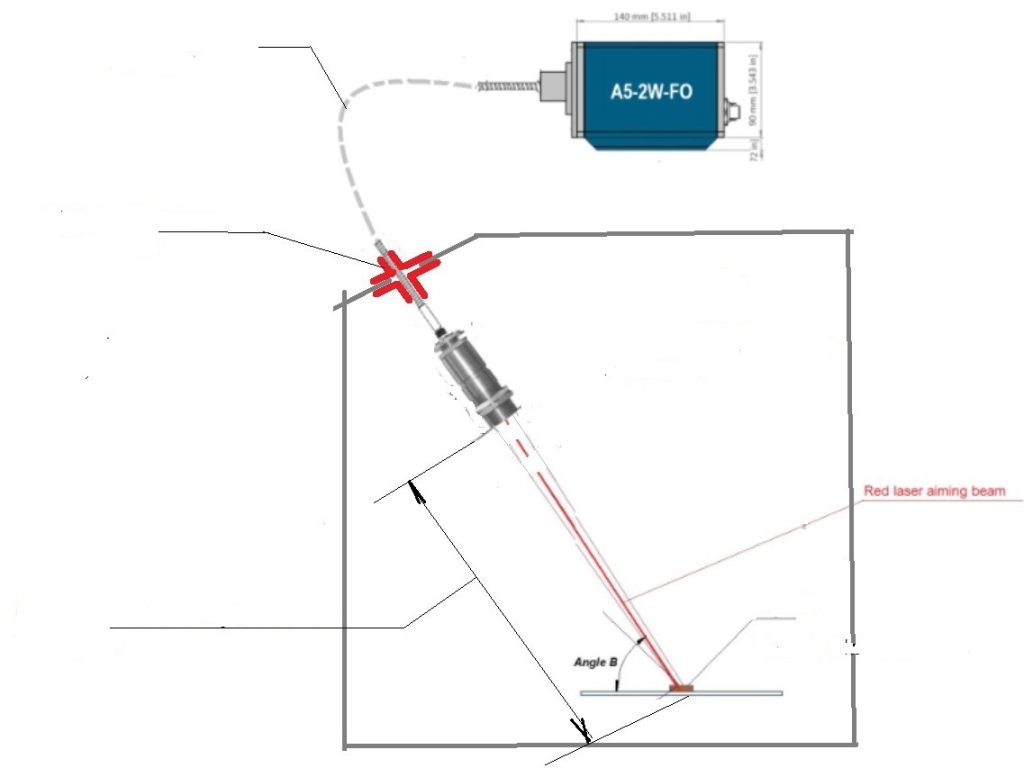

Version 2 – Internal Optical Head (inside chamber):

- Optical head is mounted inside the vacuum chamber

- Direct line-of-sight to the target

- Requires KF40/CF40 feedthrough for fiber cable

- Advantage: No transmission loss through a window

- Consideration: Head must be vacuum compatible and resistant to chamber environment

- Focus Spot Size vs. Working Distance

- The client specified a focus size between 5 mm and 10 mm.

- Our team highlights the need to clarify the working distance (distance from the sensor to the target) to validate whether the optics can achieve this spot size accurately.

- Misalignment at close focus distances can result in partial spot coverage, leading to signal degradation or inaccurate readings.

- 3. Importance of Defining Minimum Temperature (Tmin)

- While the client specified a maximum of 2200°C, the minimum temperature (Tmin) is crucial to finalize the spectral range and optimize the dual-wavelength detection.

- If Tmin is significantly lower (e.g., <700°C), the pyrometer must be configured to provide stable readings even in low signal scenarios, especially through semi-transparent environments within the chamber.

Watch: Custom Dual-Wavelength Pyrometer Design – Engineering Analysis for High-Temp Vacuum Applications

Summary & Recommendations

To develop the optimal solution, our expert recommends:

- Confirming the exact target size and working distance

- Clarifying whether a windowed or in-vacuum installation is preferred

- Specifying Tmin in addition to Tmax

- Reviewing environmental conditions inside the chamber (e.g., pressure, gas type) that may influence spectral transmission

This case demonstrates the importance of collaborative customization in high-temperature, high-precision applications—and how AST’s engineering team works side-by-side with clients to deliver tailored solutions.