Advanced Temperature Monitoring in Aluminum and Non-Ferrous Materials

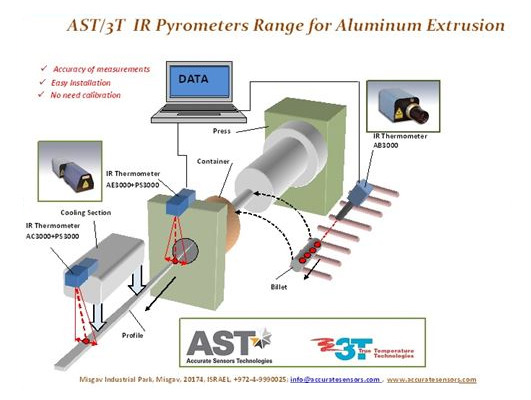

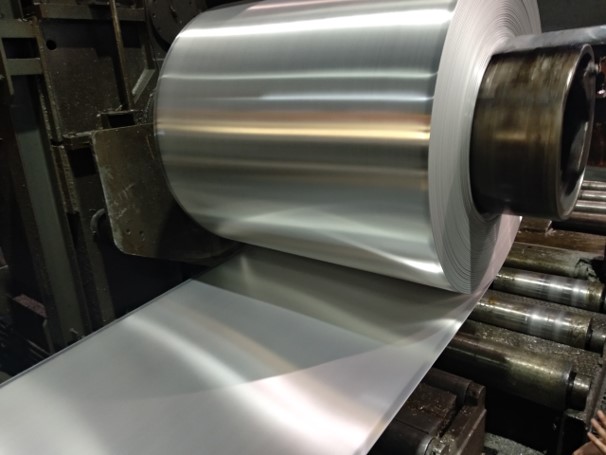

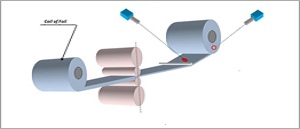

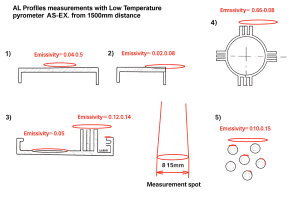

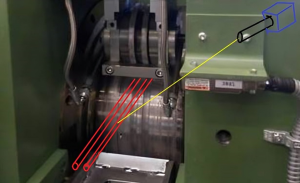

Temperature Monitoring in Aluminum and Non-Ferrous metals is an integral part of the production line. Successful temperature measurement of ‘non-grey body’ materials, such as aluminum, requires using multi-wavelength sensors to compensate for the complex emissivity characteristics of these materials. Aluminum’s emissivity varies depending on factors like alloy composition, surface oxidation, texture, contamination, and crystal structure. These variations make it essential to use advanced, non-contact pyrometers to ensure reliable thermal monitoring throughout the extrusion, rolling, and casting processes

Looking for more industrial infrared pyrometers?

Explore our complete range of Aluminum Pyrometers for Extrusion, Casting, Rolling, Forging

Explore More: Related Technologies & Industry Solutions

Download Related Resources

Discover Expert Insights in Infrared Temperature Measurement for Aluminum and Other Non-Ferrous Materials

Minimum Temperature of Aluminum – Understanding Its Behavior in Extreme Conditions

Discover how the Minimum Temperature of Aluminum impacts strength, ductility, and performance in cryogenic and aerospace applications.

Aluminum Rod Temperature Measurement Without Reference Data

Aluminum Rod Temperature Measurement without reference data – learn how to ensure accuracy using infrared pyrometry in challenging conditions.

Types of pyrometers

Type of pyrometers explained: Learn how to choose between single, two-, or multi-wavelength pyrometers based on emissivity, wavelength, and installation needs.

What Is A Pyrometer

What is a pyrometer? Learn how this infrared optical device measures temperature remotely using radiation, filters, and photodetectors – explained simply.

Aluminum Forging Temperature Measurement- Complete Guide

Optimize Aluminum Forging Temperature Measurement with advanced pyrometers for billets and bars. Ensure accuracy, reduce rejection rates, and control forging

Temperature Measurement in Ferrous and Non-Ferrous Rolling & Continuous Casting – Complete Guide

Explore precise infrared pyrometers and smart sensing systems for aluminum and steel temperature measurement in Rolling & Continuous Casting lines.