Mastering Temperature Measurement of Metals

Temperature Measurement of Metals plays a vital role in today’s metal processing industries, directly impacting product quality, energy efficiency, and operational performance. Whether you’re working with iron, steel, or stainless alloys, mastering how and where to measure temperature accurately can mean the difference between a flawless finish and costly defects. This guide consolidates proven strategies, sensor technologies, and best practices for implementing precise, real-time temperature control across high-temperature applications like heat treatment, annealing, casting, and rolling.

Table of Contents

What You’ll Learn in This Guide

In this guide, you’ll discover:

- Why accurate temperature measurement is essential in modern metal processing

- How infrared pyrometers overcome emissivity and environmental challenges

- Key applications: furnace exit, hot zones, bright annealing lines, and more

- How to choose the right pyrometer for steel, iron, or stainless surfaces

- Installation and calibration tips to ensure measurement reliability

- Real-world use cases and sensor configurations from AST solutions

Whether you’re improving your bright annealing line or optimizing furnace output in a rolling mill, this guide equips you with the tools and insights needed to make temperature work for your process.

Introduction: Why Precision Matters in Metal Processing

Precise temperature control in metal processing—across iron, steel, and bright annealing—is essential for achieving desired mechanical properties, surface quality, and process reliability. From the liquid bath at the furnace exit to final surface finishing, inaccuracies can lead to cracks, poor ductility, scale formation, or corrosion susceptibility. This guide walks through key infrared measurement applications and best practices to ensure reliable outcomes in industrial metal treatments.

Technologies & Applications

- Non‑Contact Infrared Pyrometry for Iron & Steel

- Targeted for high-temperature applications (300–3000 °C), especially at furnace exits, rolling mills, and welding lines.

- AST’s A5-1W, A5-2W, and A450 single / dual-wavelength pyrometers offer ±0.25% accuracy, real-time emissivity correction, and laser targeting—all in rugged form factors.

- Ideal in harsh environments, where contact thermometers like RTDs are impractical.

- Specialized Sensors for Bright Annealing Plants

- In bright annealing of stainless tubing, accurate temperature (~1040 °C) is vital to prevent surface defects like cracks or discoloration.

- AST uses A450 pyrometers via protected sight glass into closed induction chambers under inert atmosphere (argon/hydrogen), delivering reliable real-time readings post-annealing.

Key Calibration & Design Considerations

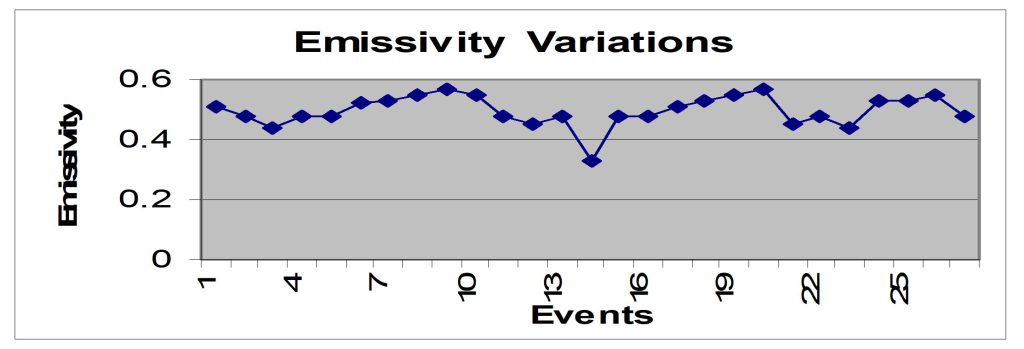

- Emissivity variations: surfaces can vary greatly—shiny vs. oxidized steel, or stainless tubes—so use single or dual-wavelength sensors with real-time emissivity compensation.

- Environment protection: use water-cooled or air-purge housings, observation windows, and robust enclosures to resist steam, scale, dust, or spray.

- Non-contact placement: safe installation outside furnace doors or annealing windows avoids high thermal stress zones while ensuring line-of-sight accuracy.

The chart shows how surface emissivity can fluctuate significantly during iron and steel processing, making traditional single-wavelength pyrometry unreliable without compensation.

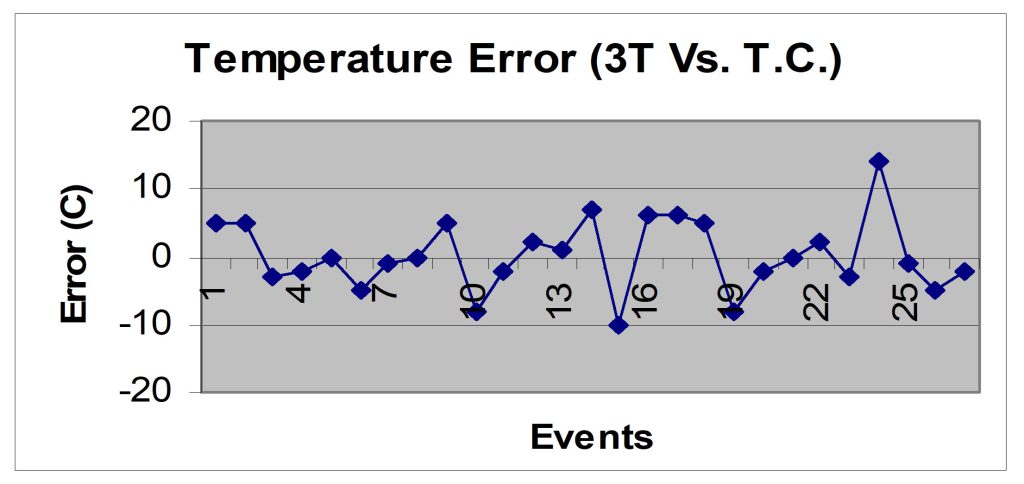

The graph illustrates the error range between 3-wavelength pyrometers and thermocouples under changing emissivity conditions. Multi-wavelength systems significantly reduce error.

Best Practices & Recommendations

- Select appropriate wavelength and model based on application temperature and surface type (A450 for annealing; A5 series for broader use).

- Enable real-time emissivity correction and adjust analog/digital outputs for PLC or automation integration.

- Prioritize rugged housing and clear sight paths to maintain measurement integrity over time.

Watch- Accurate Temperature Measurement of Iron & Steel – Non-Contact Infrared Pyrometers

Summary

This guide highlights the importance of accurate, non-contact infrared temperature measurement across iron, steel, and bright annealing processes. With advanced pyrometer technologies, emissivity compensation, and robust industrial designs, manufacturers can ensure process consistency, product quality, and operational safety—even in the harshest environments.