Blackbody Pyrometer Verification : Mastering Accurate Temperature Calibration

Blackbody Pyrometer Verification is a critical process to ensure accurate and consistent temperature readings in high-precision industrial applications. In this guide, we walk through the essential steps of verifying AST pyrometers using a blackbody reference source and a calibrated master pyrometer. From setup and software use to tolerance evaluation, this process guarantees sensor reliability, compliance, and measurement confidence across thermal systems.

Table of Contents

Watch- Pyrometer Blackbody verification Step-by-Step with AST Software

Why Pyrometer Verification is Important

Even in the most advanced non-contact temperature sensors, long-term use or challenging environmental conditions may cause drift. Verifying the pyrometer against a known reference (BB source) ensures:

- Reliable performance across production lines

- Compliance with quality assurance protocols

- Confidence in measurement precision, even under extreme conditions

Step-by-Step Guide to Verifying AST Pyrometers

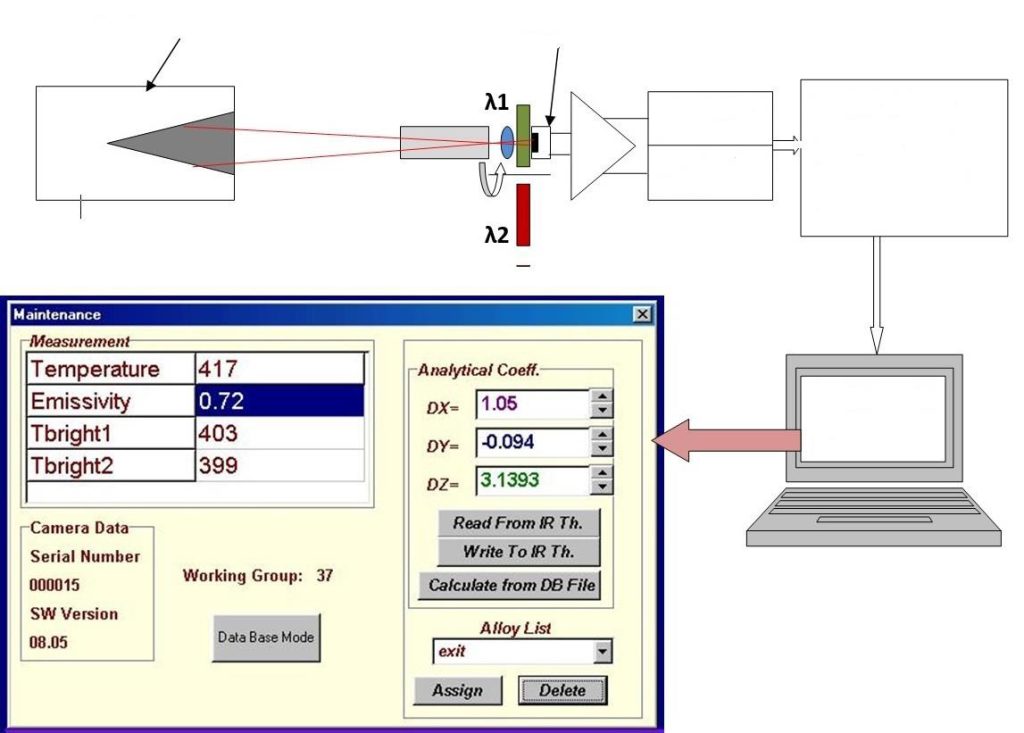

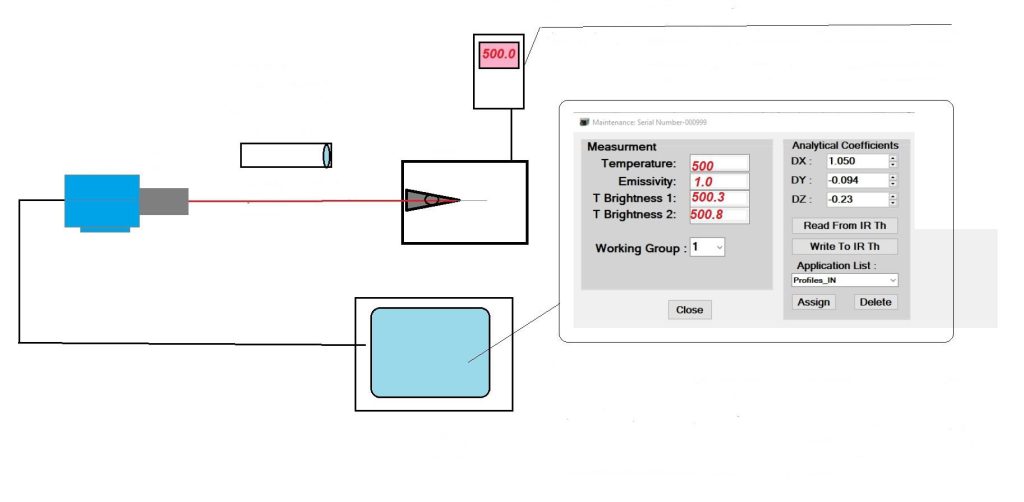

- Launch AST Software & Open the Maintenance Screen

Connect the AST pyrometer to your PC and launch the relevant AST application software. Navigate to the ‘Maintenance’ screen to access calibration-related readouts.

- Understand the Reference: BB vs. Master Pyrometer

During verification, compare:

- The reading of the pyrometer under test

- The reading of a master/reference pyrometer

Important Note: The BB controller’s display is not always accurate. It may deviate by several degrees from the actual emitter temperature. The master pyrometer provides the correct reference.

- Build a Correction Table

Create a table comparing:

- The BB controller temperature setting

- The reading from the master pyrometer

This table allows you to calculate the correction factor for the BB controller at various temperature setpoints.

- Set the Corrected BB Temperature

Adjust the BB controller to reflect the corrected temperature determined from your comparison table.

- Position the Pyrometer Properly

Align the AST pyrometer in front of the BB source at its designated working distance to ensure the full measurement spot is within the BB emitter area.

- Read T Brightness Values

From the AST maintenance screen, read the values for:

- T Brightness 1

- T Brightness 2

Both values should be within ±1°C of the actual temperature measured by the master pyrometer (as recorded in your comparison table).

- Repeat for Additional Temperature Points

Change the BB controller setting to another required temperature and repeat the entire process, recording the T Brightness values at each point.

Final Output: Verification Certificate

Upon completing the verification across multiple temperatures:

- Compile the comparison results

- Ensure T Brightness 1 & 2 are within tolerance across all test points

- Generate a verification certificate confirming that the pyrometer is within spec

Verification Summary

The goal of this process is to validate that the AST pyrometer accurately reflects the BB emitter temperature, as confirmed by a calibrated master pyrometer. This is done by comparing the corrected BB temperature to the T Brightness 1 and T Brightness 2 values on the maintenance screen.

Looking for more industrial infrared pyrometers?

Explore our complete range of Non-Contact Infrared Temperature Sensors for every application