Mastering Aluminum Forging Temperature Measurement

Mastering Aluminum Forging Temperature Measurement is essential for achieving consistent quality and efficiency in forging aluminum billets and bars. Precise temperature monitoring prevents defects like cracks, improper grain structure, and uneven deformation—ensuring reliability in demanding industries like aerospace and automotive.

Table of Contents

Why Temperature Measurement Matters in Aluminum Forging

Accurate temperature control is critical in aluminum forging because:

- Material flowability depends heavily on forging temperature—too low leads to cracks, too high weakens mechanical properties.

- Microstructure and grain size are temperature-sensitive, directly impacting strength and ductility.

- Process efficiency: controlling temperature minimizes energy waste and rejects.

Measurement Technologies and Industrial Applications

- Infrared Pyrometry for Billets & Bars

Non-contact infrared pyrometers enable fast, accurate readings right after heating and before forging:

- Suitable for round billets or flat bars.

- High-speed detection ensures real-time monitoring without interrupting production.

- Multi-Wavelength Sensors for Emissivity Compensation

Aluminum’s reflective surface and oxidation can affect accuracy. Multi-wavelength pyrometers dynamically adjust for emissivity changes—delivering consistent readings under varying surface conditions.

Calibration, Environmental Challenges & Setup

- Emissivity and oxidation: aluminum oxide alters surface emissivity—requires adaptive sensor calibration or multi-wavelength tech.

- Environmental interference: dust, scale, and ambient heat can distort readings—proper sighting windows, shielding, or cooling jackets are vital.

- Real-time adjustment: sensors should update calibration dynamically to maintain accuracy during uneven heating.

Best Practices & Integration Tips

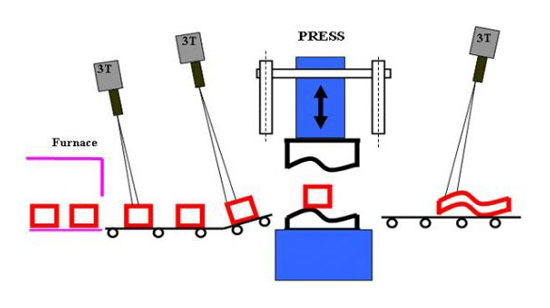

- Optimal placement: install sensors between furnace discharge and press to capture the true forging temperature.

- Initial calibration: start with empirical values and refine using thermocouples.

- Emissivity handling: enable automatic adjustment when oxidation starts post-furnace.

- System integration: connect sensors via analog or digital interfaces to PLC/DCS for live feedback and process control.

Video Demonstrations

Revolutionizing Aluminum Forging: Accurate Sensors' Pyrometer Solutions

Temperature Control of Aluminum Billets After Furnace – Accurate Measurement Solutions

Summary of Aluminum Forging Temperature Measurement

In “Mastering Aluminum Forging Temperature Measurement,” we explored how precision infrared pyrometry—including multi-wavelength sensors—ensures accurate monitoring of aluminum billets and bars. These solutions address emissivity shifts, environmental pressure, and calibration challenges, providing manufacturers with actionable insights to maintain quality, reduce defects, and automate forging processes.

Looking for more industrial infrared pyrometers?

Explore our complete range of Aluminum Pyrometers for Extrusion, Casting, Rolling, Forging