Mastering Aluminum Extrusion Temperature Measurement : Your Complete Guide

Welcome to the ultimate Aluminum Extrusion Temperature Measurement guide from Accurate Sensors Technology, where we consolidate essential insights from across our site into one comprehensive resource. This guide delves deep into best practices and advanced techniques for temperature monitoring in aluminum extrusion, ensuring manufacturers achieve peak quality, efficiency, and process control.

Table of Contents

What You'll Learn in This Guide

This all-in-one manual brings together proven methods and technologies featured across our site:

- Accurate, non-contact infrared pyrometry for billet heating and die exit stages, crucial for maintaining target ranges under harsh conditions

- Advanced pyrometer solutions, including ratio and multi-wavelength types, designed to overcome emissivity changes, dust, steam, and variable surface properties

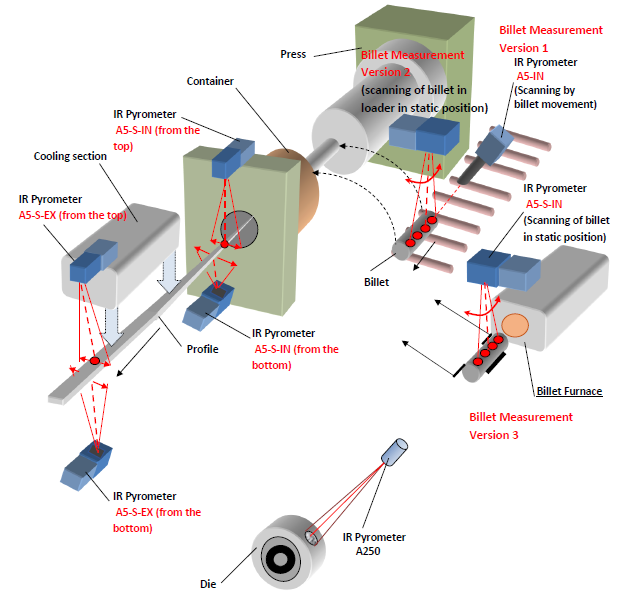

- Scanning systems (e.g., multi-cavity scanners) that deliver thermal profiles across billets and profiles for tighter process control

- Real-world applications and data, illustrating how precise temperature measurement resolves issues like uneven heating, surface defects, and scrap reduction

Why Aluminum Extrusion Temperature Measurement Matters

Temperature is the single most crucial parameter in aluminum extrusion, directly affecting production efficiency, profile quality, and equipment longevity. From controlling billet heating to precise monitoring of cooling, each stage demands accurate, real-time data to avoid defects, reduce waste, and optimize throughput.

How This Guide Is Structured

This guide is divided into three clearly defined sections:

A. Aluminum Billet Temperature Measurement at Furnace Exit- Ensuring each billet enters the extrusion press at the correct temperature.

B. Profile Temperature Measurement at Die Exit – Capturing the thermal state of the freshly extruded profile for quality control.

C. Monitoring Aluminum Profile Extrusion Cooling Rate – Tracking 10–15 meters downstream to analyze cooling rate and final product properties.

A. Aluminum Billet Temperature Measurement at Furnace Exit

1. Why Billet Temperature Measurement Matters

Measuring the temperature of aluminum billets as they exit the furnace is a critical step in the extrusion process. Accurate temperature control ensures consistent metal flow, minimizes defects, and improves overall product quality. Improper temperature measurement can lead to uneven extrusion, surface defects, and increased material waste.

2. Measurement Techniques and Industrial Applications

Accurate Sensors Technologies offers a wide range of infrared pyrometers and scanners designed specifically to handle the challenges of non-contact temperature measurement in aluminum extrusion environments, especially where emissivity is low and surface conditions are constantly changing.

- Portable and Fixed Multi-Wavelength Pyrometers – A5-EX-FO Series

The A5-EX-FO series includes both fixed-mount and portable multi-wavelength infrared pyrometers designed specifically for aluminum extrusion environments.

Fixed A5-EX-FO

- Mounted at key points like the furnace or die exit

- Provides real-time, continuous temperature monitoring

- Offers seamless integration with process control systems

- Ideal for high-volume, automated production lines

Portable A5-EX-FO

- Handheld version ideal for flexible spot-checks

- Can be used at both the furnace exit and die exit

- Delivers fast, accurate temperature readings regardless of emissivity or surface condition

- Valuable for troubleshooting, QA verification, and process optimization

These two models allow for full coverage of critical temperature points, ensuring that both operators and engineers can maintain high-quality standards in real time.

Live Demonstration – A5-EX-FO Portable Pyrometer for Aluminum Extrusion

This video highlights the A5-EX-FO handheld pyrometer being used during a real extrusion run. It shows temperature checks performed at both the furnace exit and the die exit, emphasizing the device’s precision, speed, and mobility.

- Infrared Pyrometers – Spot vs. Multi-Wavelength

- Single-wavelength pyrometers (e.g., A150 series) are suitable for basic applications but are often affected by surface conditions such as oxidation or contamination. These factors can reduce accuracy due to emissivity variation.

- Multi-wavelength pyrometers, however, analyze several infrared bands and use advanced algorithms to compensate for emissivity shifts. They provide more reliable results in real-world aluminum extrusion settings, especially in the 160–550 °C range typical of billet heating.

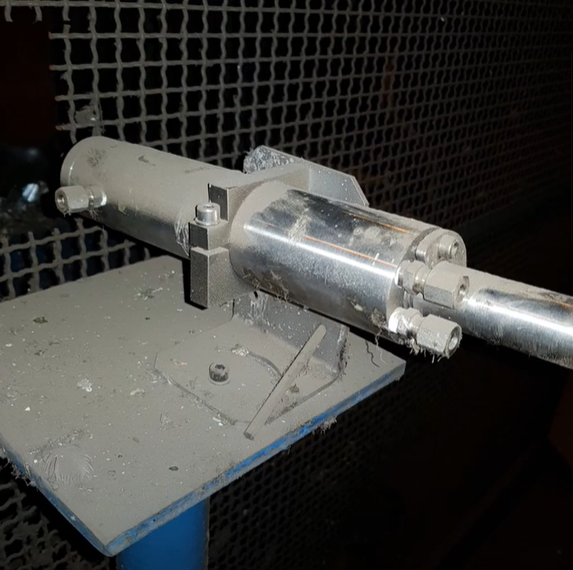

Multi-wavelength pyrometer- the measurement spot scans the billet during billet linear movement.

- Infrared Line Scanners (e.g., A5-S-IN)

- Line scanners scan across the billet length to generate a complete thermal profile.

- A standard scan time is approximately 32 seconds for 1.45 meters of billet, with a spatial resolution of 4–6 mm.

- This method helps detect uneven heating, surface anomalies, and hotspots that could be missed by single-point sensors.

- Furnace Integration – Induction Furnace Considerations

Measuring billet temperature inside induction furnaces introduces several technical challenges, including:

- Electromagnetic interference

- Variable surface emissivity

- Limited space for sensor installation

- Inconsistent thermocouple reliability

To address these, AST recommends using non-contact infrared pyrometers such as the A5-EX (Tmin = 200 °C) or A5-IN (Tmin = 330 °C), positioned between the induction coils. These models are optimized for high-temperature zones and deliver accurate readings with minimal maintenance.

Minimum working distance:

A minimum of 500 mm between the pyrometer and the target is required for accurate spot size and focus. Closer distances may lead to defocusing and measurement errors.

Watch the Engineering Demo

For detailed guidance on sensor positioning, spot size vs. distance, and choosing the right model for each furnace zone:

Includes illustrations, working distance examples, and real installation insights.

3.Challenges and Calibration

Measuring aluminum billet temperature poses unique challenges:

- Variable emissivity due to oxidation or inconsistent surface finish

- Environmental interference from steam, dust, or surrounding heat sources

- Induction interference in electromagnetic environments

AST’s technologies are engineered to minimize these effects through optical filters, algorithmic compensation, and proper sensor placement and calibration.

4. Best Practices and Recommendations

- Install sensors approximately 3.5 meters from the induction furnace to balance accuracy and longevity.

- Adjust scanning parameters according to billet length and line speed to ensure full thermal profiling.

- Use multi-wavelength pyrometers in situations with fluctuating surface emissivity.

- Portable devices like the A5-EX-FO are ideal for validating readings at the furnace exit and die exit, especially in dynamic or mobile production settings.

5. Watch: Billet Temperature Monitoring in Induction Furnaces

Infrared Temperature Control for Aluminum Billets in Induction Furnaces

Multi-Wavelength Pyrometers for Precise Aluminum Billet Temperature Control

Precise Aluminum Billet Temperature with the A5-S-IN Infrared Scanner

A150 Pyrometer for Precise Aluminum Billet Temperature Control

A5-S-IN Infrared Billet Scanner – Real-Time Thermal Profiling for Aluminum Extrusion

Introducing the A5-EX-FO Portable Pyrometer Designed Specifically for Aluminum

Extrusion Temperature Measurement – A5-EX-FO Pyrometer

Engineering ping pong temperature of billet inside an induction furnace

6. Part A Summary – Accurate Billet Temperature Measurement at Furnace Exit

In this section, we’ve explored the critical role of temperature measurement at the billet furnace exit. From fixed multi-wavelength pyrometers and scanning systems to portable diagnostic tools like the A5-EX-FO, Accurate Sensors Technologies provides a complete set of solutions for precise and reliable thermal monitoring in aluminum extrusion.

B. Profile Temperature Measurement at Die Exit

1. Introduction: Why Die-Exit Temperature Matters

Monitoring the temperature of the aluminum profile immediately after it exits the die is crucial for controlling material properties such as hardness, strength, dimensional stability, and cooling behavior. Accurate real-time measurement helps prevent defects like extrusion lines, surface cracks, and inconsistent profile dimensions, leading to higher quality and reduced scrap rates.

2. Measurement Technologies and Best Practices

Accurate and consistent measurement of the profile temperature at the die exit is essential to ensure proper material properties, reduce defects, and maintain extrusion quality. Accurate Sensors Technologies offers both fixed and scanning infrared pyrometers tailored to this specific stage in the process.

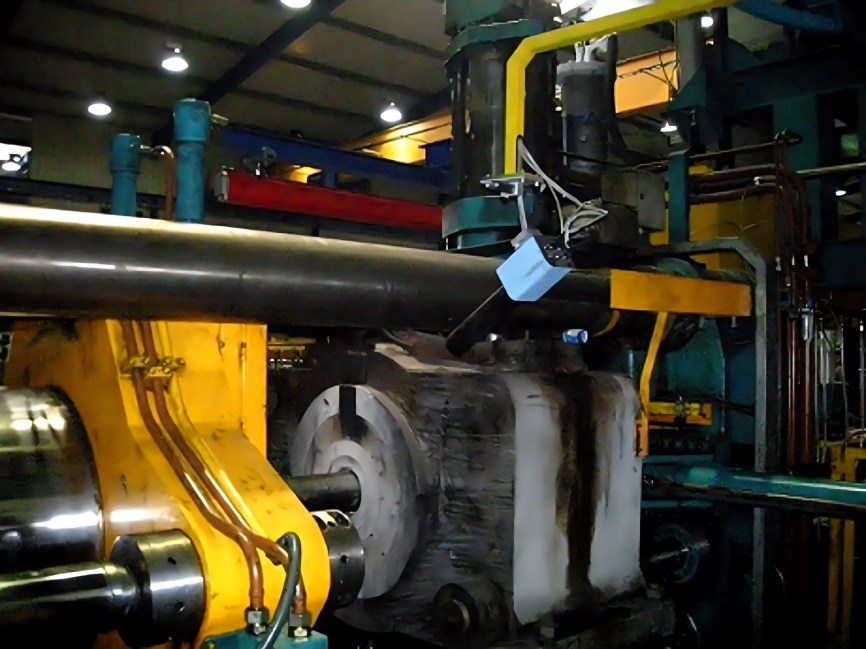

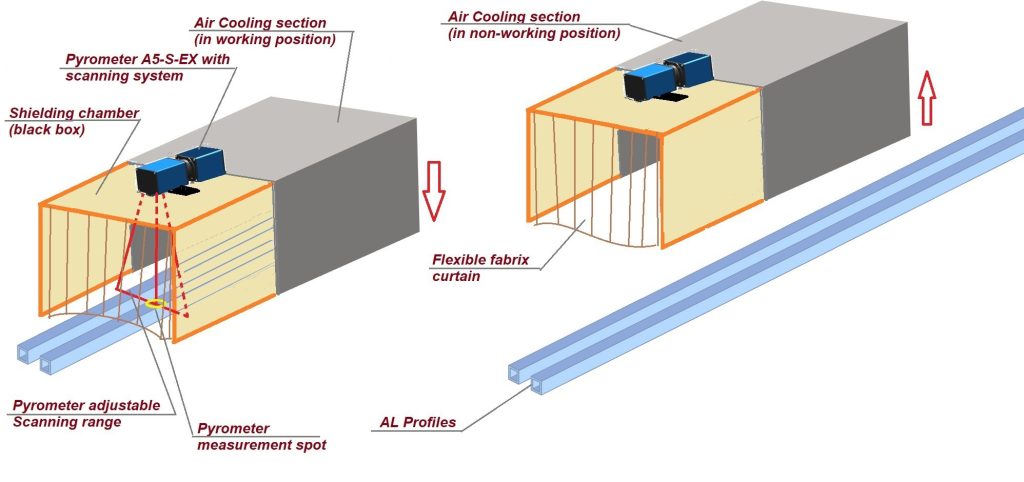

- Fixed Pyrometers for Die-Exit Temperature (A5-EX and A5-S-EX)

- The A5-EX and A5-S-EX pyrometers are designed for continuous, non-contact measurement of aluminum profiles immediately after extrusion.

- These models are optimized for dynamic conditions near the die exit, providing real-time, accurate temperature data.

Installation Guidelines

Mounting height recommendations:

- A5-EX: ~800–1000 mm above the profile

- A5-S-EX: ~800–1300 mm above the profile

- Use a height-adjustable bracket to ensure proper aiming and facilitate cleaning access

Initial calibration:

- Start with factory defaults: Dx = 1.02, Dy = -0.032

- Fine-tune settings on-site using a thermocouple for enhanced accuracy

- Ensure the sensor is shielded from heat, dust, and vibration using protective enclosures if necessary.

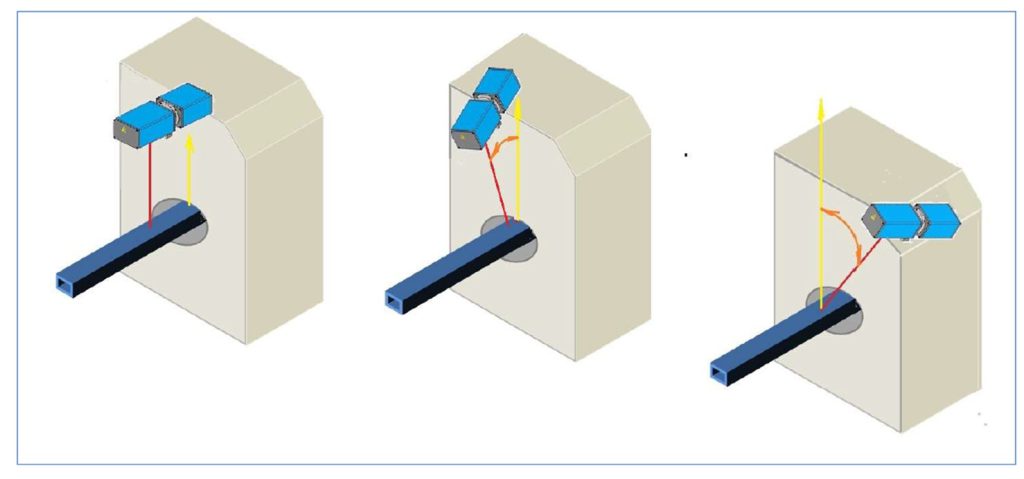

This image illustrates multiple mounting options for fixed pyrometers like the A5-EX or A5-S-EX, based on die housing design and available space. Proper alignment ensures consistent readings and easy maintenance access.

- Scanning Solutions at Die Exit

- Scanning pyrometers offer full thermal profiling across the entire profile width, enabling detection of hot spots, edge cooling, and uneven flow.

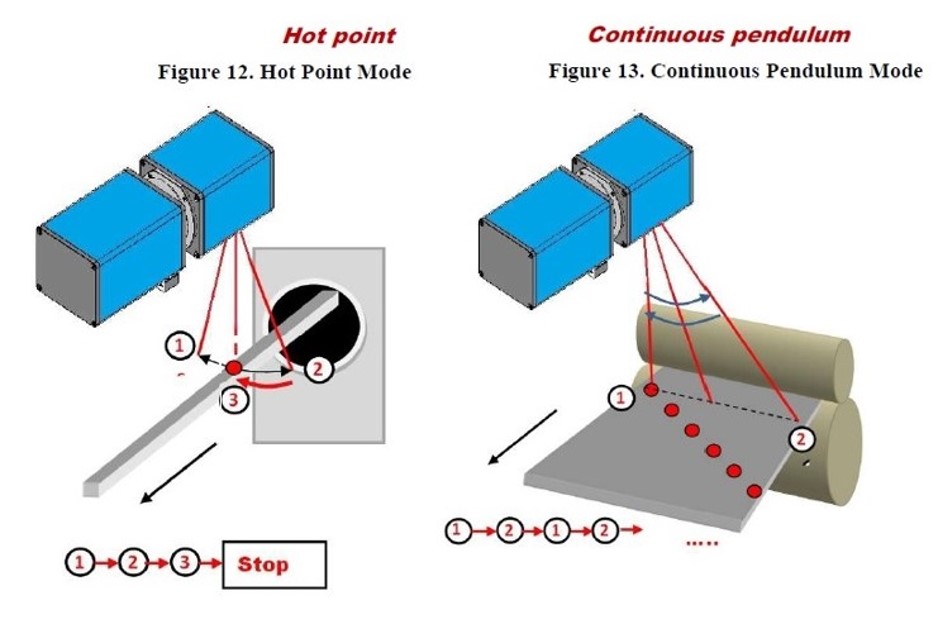

The system supports multiple scanning modes:

1.Hot-spot mode – locks on the highest temperature point

2.Continuous pendulum scan – sweeps in a repeated motion

3.One-shot scan – performs a single pass per profile

4.Program-point scan – pauses at up to 20 fixed positions

- Scanning solutions are particularly useful for multi-cavity dies, complex profiles, or situations where temperature gradients across the profile need to be detected and controlled.

- These systems can automatically trigger process alarms or activate control mechanisms via programmable outputs.

flexibility of the scanning modes available with the A5-S-EX pyrometer — particularly the “One-Shot Scan” and “Program Points Mode,” ideal for multi-profile extrusion lines

- System Integration and Output Options

Both fixed and scanning pyrometers support a wide range of analog and digital outputs, including:

- Analog: 4–20 mA, 0–10 V

- Digital: RS232, RS485, USB, CANbus, Bluetooth

- Seamless integration with PLCs, SCADA systems, and visualization dashboards is supported via AST’s proprietary AST NET software.

- Users can log profile temperature data, generate trend reports, and apply real-time corrections to process parameters.

- Additional Considerations for Narrow Multi-Cavity Extrusions

Temperature measurements with scanning pyrometers in multi-cavity extrusion (e.g., narrow strips) introduce special challenges:

- Fluorescent or white LED tunnel lamps are recommended; otherwise, ambient lighting must be turned off during measurement to avoid signal interference.

- When scanning multiple narrow profiles, the measurement spot (13–15 mm) may sometimes land off-center or partly off the metal, especially as the strip shifts laterally during extrusion. This leads to inaccurate readings or even “out-of-range” results.

- s. Using three program points per strip can exaggerate this effect without improving accuracy.

AST NET software visualizes these variances, and analysis shows that accurate results are obtained when a single point is set at the center of each profile. More points add complexity without improving precision.

Recommendation: For narrow extruded profiles, use one centered measurement point per strip to ensure optimal and stable temperature data.

3. Real-World Configuration and Integration

- Single-Pyrometer vs. Scanning Systems

- Fixed A5-EX/A5-S-EX pyrometers provide continuous temperature monitoring at a single point.

- Scanning systems add comprehensive thermal profiling, detecting anomalies across the width of multi-cavity profiles

- Integration with Control Systems

- Both fixed and scanning devices offer outputs in analog (4–20 mA, 0–10 V) and digital (RS232, RS485, CANbus, USB, Bluetooth) formats

- Integration enables real-time data logging, process-control feedback, and dashboard visualization via AST NET software

4. Watch: Profile Temperature Measurement at Die Exit

Accurate Temperature Measurement in Extrusion: Key Benefits of Scanner Systems

Precise Temperature Measurement in Aluminum Extrusion Process

Revolutionizing Temperature Monitoring: Multi Cavity Scanner for extrusion

Real-Time Profile Temperature Measurement in Aluminum Extrusion – A5-S-EX Infrared Sensors

A5-EX-FO Fiber Optic Pyrometer – Accurate Infrared Temperature Measurement in Harsh Environments

A5-EX-FO Fiber Optic Pyrometer in Action – Real-Time Temperature Measurement at the Press

Revolutionizing Temperature Monitoring: Multi Cavity Scanner for extrusion

6. Part b Summary – Profile Temperature Measurement at Die Exit

In Part B, we’ve outlined the essential methods for measuring aluminum profile temperature right after the die exit. Whether using fixed infrared pyrometers or advanced scanning solutions, Accurate Sensors Technologies ensures that manufacturers can maintain consistent temperature, leading to better quality, fewer defects, and more efficient extrusion processes.

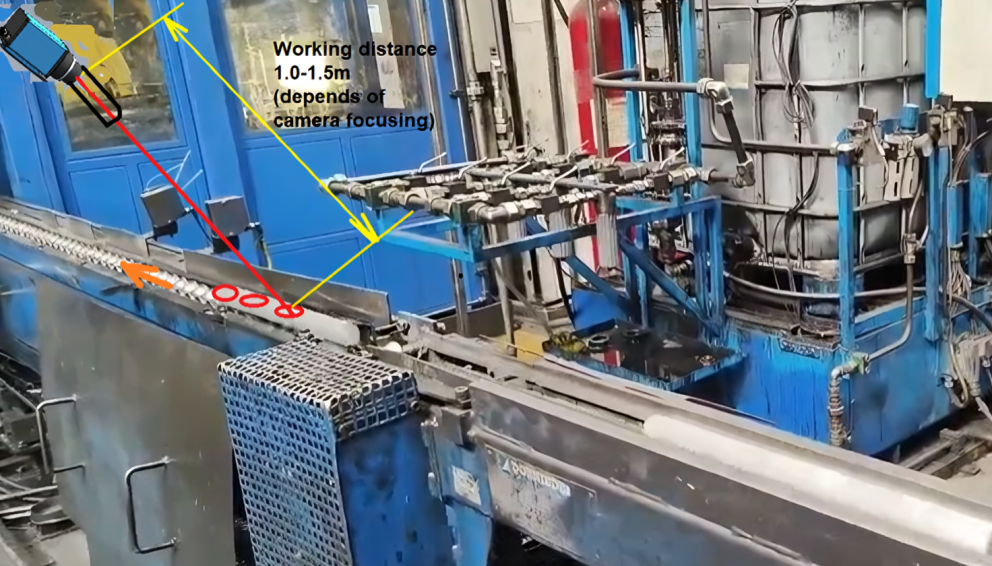

C. Profile Cooling Rate Measurement at Runout Table

1. Introduction: Why Cooling Rate Matters After Die Exit

The cooling rate of aluminum profiles immediately after extrusion plays a critical role in defining their final mechanical and metallurgical properties. Control over the cooling process—whether via air or water quenching—ensures correct dimensional stability, hardness, and strength. Minor variations in cooling rate can introduce internal stresses or deformation in the profile

2. Measurement Technology and Setup

Accurate Sensors Technologies offers advanced non-contact pyrometers that measure true surface temperature of extruded profiles downstream from the die, enabling precise cooling rate calculation.

- Measurement range: 200–600 °C

- Emissivity compensation: ε = 0.1 (200 °C) → 1.0 (600 °C)

- Accuracy: ±1%

- High sensitivity ensures detection of small temperature changes

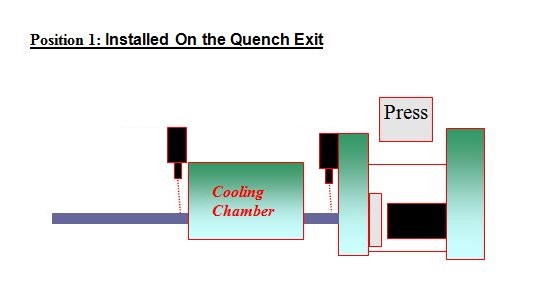

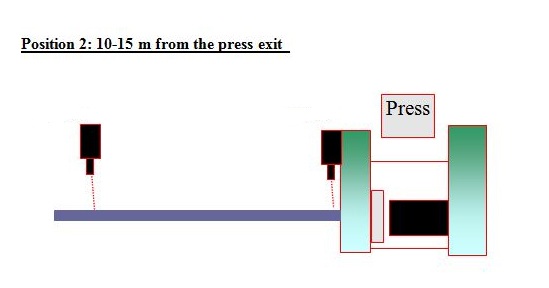

- Pyrometer Placement Options

Two optimal installation points are recommended along the extrusion line:

At die exit (press exit)

10–15 meters downstream, above the cooling table or quench area

These locations allow comparison of temperature before and after cooling to calculate actual cooling rate.

- Advanced Considerations in Measuring Aluminum During Cooling

Measuring the cooling phase is especially challenging due to aluminum’s low emissivity, which impacts accuracy—especially at temperatures below 200 °C (392 °F). Key technical considerations include:

- Wavelength Selection: A pyrometer wavelength between 1.6–3.0 µm is required to detect low temperatures reliably.

- Light Reflection Interference: Bright aluminum surfaces reflect ambient light into the sensor, distorting readings—requiring shielding and careful placement.

- Emissivity Variation: As aluminum cools, its emissivity changes. Only a multi-wavelength pyrometer can compensate for this and provide accurate readings throughout the process.

This section is further supported by demonstration videos illustrating these challenges and how AST’s systems overcome them in real-world environments.

3. Cooling Rate Calculation and Example

- Cooling rate is determined using:

Cooling rate (°C/min) = ΔT / Δt

ΔT = Temperature_exit − Temperature_quench (or 240 °C)

Δt = Travel time = Distance / Extrusion speed

(Note: 240 °C is the indicated lower limit of reliable pyrometer readings; below this, the analog/digital signal indicates “out of range”)

Real-world example:

- Flat profile: ΔT = 169 °C

- Tubular profile: ΔT = 93 °C

This shows how different geometries cool at different rates under identical conditions

4. Water vs. Air Quench Considerations

- Water quench: After cooling, profile temperature often drops below 100 °C—this triggers an “out-of-range” signal, confirming sufficient cooling

- Air cooling: When profiles remain above 250 °C, accurate pyrometer reading is maintained. The AC3000 model supports this range effectively and compensates for shape complexity accuratesensors.com .

Note:

- AC3000 (ε=0.1) can measure down to 170 °C, and

- FR3000 (ε=0.1) down to 145 °C

5. Integration, Data Collection & Process Optimization

- Pyrometers can be integrated using analog outputs (4–20 mA) or digital interfaces (RS232, etc.) to capture real-time temperature data for analysis.

- Monitoring different profiles under similar cooling conditions often reveals variability—data-driven adjustments to extrusion speed, air/water flow rates, or cooling table length can optimize quality

- Systems such as AST NET visualize and log cooling curves, enabling feedback control and traceability.

Watch: Accurate Infrared Temperature Measurement During Aluminum Extrusion Cooling

6. Part C Summary- Profile Cooling Rate Measurement at Runout Table

In this section, we’ve seen that monitoring profile cooling rate after die exit is essential for controlling mechanical properties and ensuring consistent extrusion quality. Accurate pyrometers placed strategically along the runout table—capable of precise readings in the 200–600 °C range—enable manufacturers to measure true cooling rates, compare profiles, and make data-driven adjustments to improve yield and reduce defects.