Continuous Control of Thermodynamic Temperature in Extrusion, Rolling and Forging of Aluminum Alloys

Prepared by— Dr. E.D. Glazman, Chief Scientist, R. Goshen, T. Kornfeld, S. Levy, H. Damir

Abstract

Dynamic nature of particles behavior in extrusion, rolling and forging of aluminum and its alloys almost totally rules out the possibility for contact thermometry under continuous control of thermodynamic temperature. The authors examined the basic potentialities of non-contact passive optical pyrometry for these processes. Method of optical pyrometry which provides for thermodynamic temperature measurement at unknown and varying emissivity in the range of 200-1000ºC with maximal tolerance of approximately 1% are presented in the report. Results of industrial use of designed pyrometry systems obtained over a period of years for aluminum and its alloys in extrusion in a number of large companies in the USA, Europe, Canada, Australia etc. are discussed.

Interdiction

3T-True Temperature Technologies, Ltd. enjoys a worldwide reputation for its unique pyrometers. The Company has introduced a unique line of proprietary pyrometers that use a totally new approach for remote temperature measurement. These proprietary pyrometers provide highly accurate, non-contact measurement of true target emissivity and intermediate conditions. These products are not sensitive to changes in emissivity or other target parameters and are not affected by the intermediate conditions between the pyrometer and the target. As a result, 3T’s pyrometers are the only products available today capable of handling the unstable targets and intermediate conditions commonly found in the aluminum, steel and other metals industries while still indicating the target temperature to a high degree of accuracy.

Theoretical Considrations

The dynamic nature of a real object’s behavior in extrusion, rolling and forging of aluminum and its alloys imposes substantial restrictions on the use of contact pyrometry in the mentioned processes. Non-contact, and in particular optical pyrometry, offers certain advantages. For implementation, a number of significant problems should be resolved. Among these are:

- Variable emissivity of hot billets and profiles from aluminum and its alloys during measurement

- Exposure to direct and reflected radiation from external natural or artificial light sources

- Action by the intermediate medium present between the pyrometer and the object

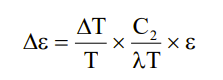

The effect of the last two mentioned excitation factors can be reduced or eliminated by different technical means, whereas as mentioned in elimination of the variable emissivity effect is of a fundamental nature. As mentioned in [1,2], this difficulty is in the first place related to the nonlinear emissivity of real objects that varies with the wavelength during the measurement. It is well known that brightness pyrometry allows high precision temperature measurements of an object in a narrow emissivity range:

As is evident from equation (1), the ε(λ,T) measurement range at a required measurement precision can be extended only by shortening the pyrometer wavelength. However, in low temperature ranges this results in a drastic increase of errors caused by the influence of the external natural and artificial radiation sources. Fig. 1 shows the spectra of a number of artificial light radiation sources used in aluminum industries. In connection with this, passive brightness pyrometry is not very popular in extrusion, rolling and forging of aluminum and its alloys, where the surface emissivity is changed in a wide range under the physical and mechanical action.

1)

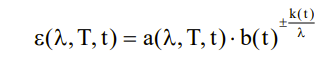

Here an attempt is made to use two-three-or multi-wave passive pyrometry with or without acquiring information about the object emissivity. In this connection the examination of maximal potentialities of passive optical pyrometry are of an interest. In a general form the emissivity of a real object can be presented by the following equation[3]:

2)

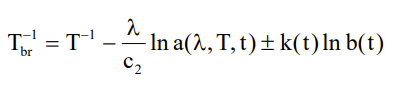

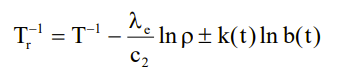

The brightness temperature (Tb) of a real object and spectral ratio temperature (Tr) can be presented as follows:

3)

4)

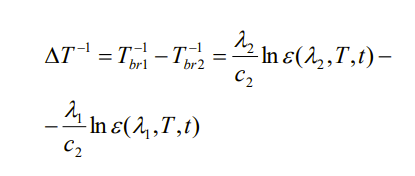

The difference between two brightness temperatures will be:

5)

Where: T – thermodynamic (true) temperature of a real object:

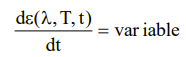

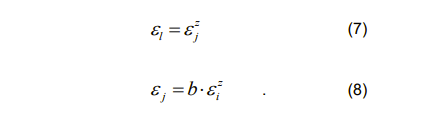

c2 =14388μxK – the second pyrometric constant in the Plank’s equation; k,b – coefficients . The examination of the above equation shows that when:

6)

passive pyrometry can measure the true temperature with precision to the second factor of the right side of equation (2) in either approximation method [4,5], or spectral ratio [6], or Hoffman-Tingwaldt [7]. Pyatta [8] and other methods in which the emissivity is presented as an exponential function [9].

and so on.

The solution of the true temperature measurement problem by the passive optical pyrometry under conditions (6) is connected with finding the error caused by the second factor of the right side of equation (2). The authors have elaborated on this approach to fit all materials, including treatment of aluminum and its different alloys in the extrusion processes – hot billets at the entrance to the press, profiles a the press exit and during their cooling, during continuous and non-continuous rolling, and during forging.

Figure 1. Energy Spectral Distribution of Xe arc, Ar arc and W halogen lamps. (Rapid Thermal Processing, Edited by Richard B. Fair, Academic Press, NYC, 1993)

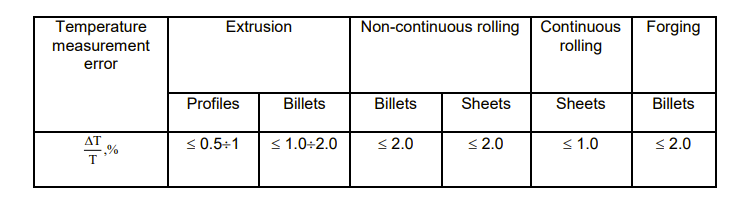

Taking into consideration the instrumental error of 3T pyrometers, metrological potentialities of passive optical pyrometry were studied to fit the mentioned processes. The experimental results of this study are listed in Table 1:

3T – Pyrometers

The block diagram of the 3T-pyrometer is illustrated in Fig. 2 in (1,2). It is a flexible multiwave pyrometric system that in every specific case enables implement action of any algorithm, including those designed both for gaining and not gaining information about ε(λ,T,t). The pyrometer algorithm and engineering design are constantly being improved upon. At present, it is possible to automatically acquisition data regarding the emissivity and automatic selection of optimal algorithms fit to measure the real temperature under variable emissivity.

The 3T pyrometric system allows either manual input of prior information about ε(λ,T,t) or use of a thermocouple via communication connectors RS-232, RS-422, RS-485.

Advantages of Pyrometer Systems for Measuring Precise Temperatures in Aluminum Extrusion Lines

- Productivity – allows for increased extrusion speed

- Quality – better profiles reduce amount of scrap produced

- Energy – Saves gas or electricity at the die furnace, billet furnace and container electrical element

Increased Press Speed – As extrusion speed is increased productivity is increased. For example, if aluminum profiles are usually extruded at a low temperature of 520ºC and the extrusion temperature is increased to 560ºC, the extrusion press speed can be dramatically increased.

Installation Locations for Pyrometers on Aluminum Extrusion Lines

The pyrometer can be positioned at the following three locations:

- press exit

- billet furnace exit or before the billet loader

- extrusion cooling table An example of this system is shown in Fig. 3

A. Press exit – By measuring the temperature of aluminum profiles at the press exit, the following advantages can be achieved:

Quality

Emissivity is a surface parameter with a value between 0 and 1. Low emissivity leads to a mirror profile surface. When low emissivity is maintained, the surface quality is higher. Pyrometer systems provide a display showing the emissivity of each profile, resulting in better profiles. When profiles are extruded at very high temperatures, for example between 580ºC to 600ºC, the product may be damaged. High quality pyrometers can prevent this damage.

Ideal Extrusion

This is accomplished by using the maximum temperature, the optimal pressing speed and minimum emissivity. In order to achieve ideal extrusion, the following data must be collected from each extrusion:

- Press speed

- Temperature

- Emissivity

- Quantity per hour

Data can be collected in the following ways:

- Manually from controller display

- By chart recorder: 0-10V from controller

- By computer: from 3T’s controller (RS 232 or RS 485 compatible).

The data is analyzed and, based on this information, instructions regarding the optimal press speed are given to the press operator. Using pyrometers, a press operator can use the information obtained, along with his experience, to achieve the best extrusion process possible.

Combined Closed Loop Control

Controller signals can be combined with a closed loop control system allowing for automatic control of press speed.

Billet Furnace Exit

By measuring the temperature of aluminum profiles at the billet furnace exit or positioning before the billet loader the following advantages can be achieved:

- Prevention of a hot or cold billet from entering the press:

A hot billet damages the profile resulting in low quality.

A cold billet causes maintenance problems.

- Better control of the billet temperature furnace temperatures allows for improved control of the furnace

- Energy – Billet temperature control can result in energy saving at the billet furnace.

At the Cooling Table

By measuring the temperature of aluminum profiles at the cooling table where profile temperatures range between 200°C-230°C the

following advantages can be achieved:

- Improved mechanical properties result in better quality

- Profiles must be cooled with precise timing.

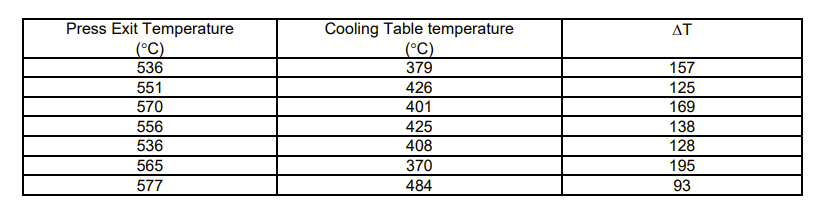

The cooling rate is a strong function of the profile shape and the contact area with the cooling rate can deteriorate the mechanical properties of the profile, by creating internal stresses and deformations. The pyrometer can be installed on a linear motion scanning motor in order to improve the temperature uniformity of the profile. Data can be collected and analyzed through analog or digital outputs. An optimal cooling rate can be adjusted based on these readings. Results collected at production facilities using pyrometers for temperature measurement show the significant variation of the cooling rate for different extruded profiles with the same cooling conditions. The measurements were provided by two pyrometers, one located 15 meters from the press exit and the other above the cooling table. In a specific case of two profiles with different shapes, one almost flat and the other tubular, a temperature drop of 169°C was measured on the flat profile, whereas the tube had a temperature drop of only 93°C (Table 2).

Conclusion

Specialized pyrometers in non-contact true temperature measurement offer the extruder a variety of systems that show the exact temperature at different locations on the press and significantly improve product quality while increasing productivity.

The 3T pyrometer system is able to accurately measure Billets at the furnace exit and

profiles at the press exit and the cooling table. Data is linked to central software that displays and analyzes it. The pyrometer system then provides all data needed to monitor and control high efficiency extrusion processes.

Reference

- Glazman E., Gochen R., Harel et. al. New Optical Pyrometer for Measuring the Temperature of Aluminum Alloys. Aluminum extrusion. The International magazine of the Aluminum extrusion, 1997, N 5, pp.24-25, 27.

- Glazman E.D. Measurement of Thermodynamic Temperate in the Extrusion Processes of Aluminum and Aluminum Alloys. Light metals, AGE, April, 1998, pp. 46-48, 50.

- Glazman E.D, Novikov I.I. Measurement of the true temperature of real bodies by selfthermal radiation. Proceedings on Thermophysical properties of substances and materials. Russia, Moscow, Gosstandart, 1991, pp. 139-149.

- Swet D. A. High Temperature - High Pressure. 1976, v. 8, pp. 493-498.

- Coates B., Metrologia, 1981, V. 17, N 3, pp. 103-109.

- Gardner I. L., Jones T.P. Davies M.R. High Temperature – High Pressure. A Six-wavelength radiation pyrometer. 1981, V 13, p.p. 459-466.

- Hoffman F., Tingwaldt C., Opthiche Pyrometry. Braunschveig, 1938.

- Pyatt E.S. British Journal of Applied Physics, 1954, V. 15, N 5, pp 264-268.

- Novikov I.I. Glazman E. D. Abramovich B.G. Russia, AN USSR Teplofisika Visokich Temperatur, 1976, V. 14, V. 5, p.1139.

- Robbins P. Who are the Superextruders? Light Metal Age Magazine, April 1997.

Looking for more industrial infrared pyrometers?

Explore our complete range of Aluminum Pyrometers for Extrusion, Casting, Rolling, Forging