High-Accuracy Pyrometers for Extrusion Temperature Monitoring

Accurate temperature control is crucial in aluminum extrusion and directly impacts:

- Productivity – Increases extrusion speed

- Quality – Enhances profile quality and reduces scrap

- Energy Savings – Reduces gas/electricity consumption in billet and die ovens

- Equipment Longevity – Extends the life of extrusion tools and machinery

Since the extrusion process is dynamic, continuous non-contact temperature monitoring using advanced pyrometers is essential.

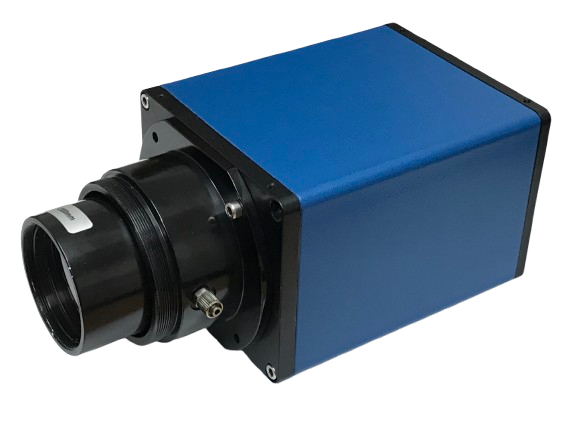

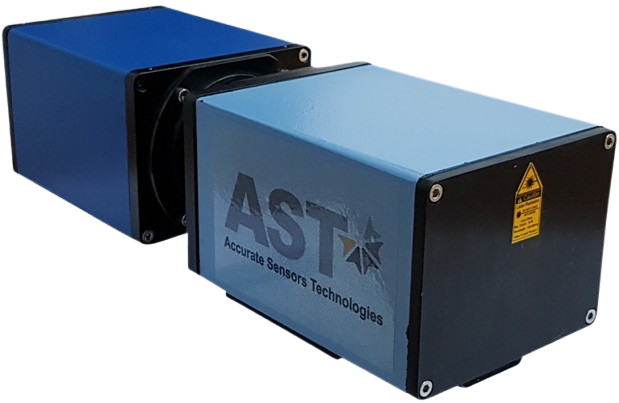

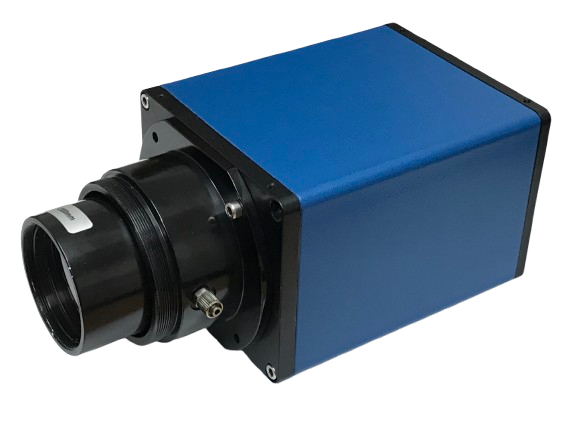

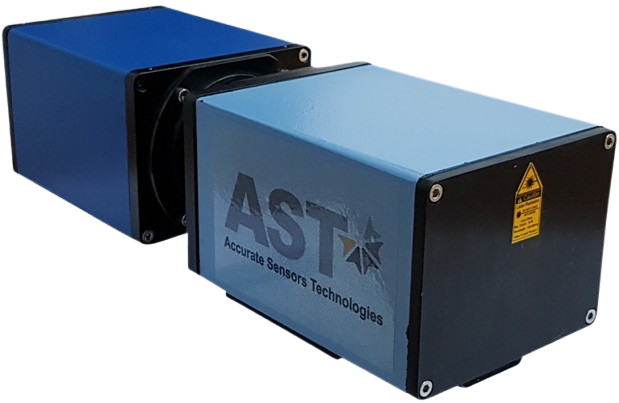

AST’s Solutions for Aluminum Extrusion

Accurate Sensors Technologies (AST) offers specialized pyrometers tailored for the aluminum extrusion industry.

Our multi-wavelength pyrometers feature advanced algorithms to ensure accurate temperature measurement—even under harsh conditions involving changing emissivity, smoke, dust, and steam.

Key Application Areas

1. Billet Heating Measurement

- Billets are typically heated to 420–500°C before extrusion

- Accurate measurement avoids pushing underheated billets into the press

- Recommended models: A5-IN and A5-S-IN

2. Extrusion Die Exit Measurement

- Profiles exit at speeds between 5–50 meters/minute

- Monitoring exit temperature ensures high-quality output and process efficiency

- Recommended models: A5-EX and A5-S-EX

Recommended Pyrometer Models for Aluminum Extrusion

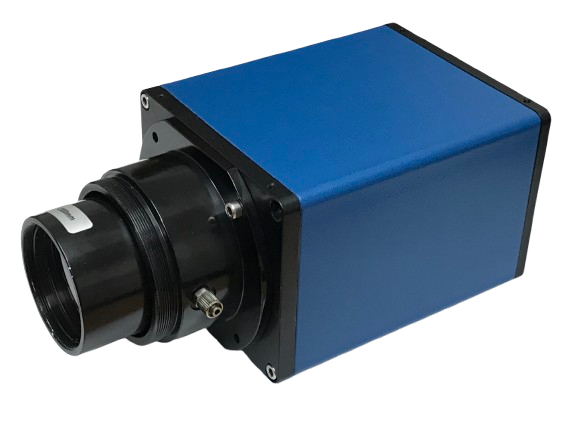

A5-IN

Standard billet monitoring.

Billet temperature measurement.

Temperature Range 350°C to 2000°C

A5-S-IN

High-accuracy, short-wavelength option.

Billet temperature measurement.

Temperature Range 350°C to 2000°C

A5-EX

Real-time monitoring of fast extrusion.

Profile temperature at die exit.

Temperature Range 105°C to 2500°C

A5-S-EX

Short-wavelength for reflective targets.

Profile temperature at die exit.

Temperature Range 105°C to 2500°C

A5-EX-FO

Fiber optic + Bluetooth communication.

Billet and profile measurement.

Temperature Range 170°C to 300°C

A5-EXL

Bluetooth, long-range laser targeting.

Shiny aluminum surface temperature.

Temperature Range 80°C to 1150°C

Why Choose AST’s Aluminum Pyrometers?

- High Accuracy – ±1% of measured value

- Reliable in Harsh Environments – Works through steam, smoke, and dust

- Laser Targeting – Pinpoint accuracy even from a distance

- Advanced Connectivity – Bluetooth, RS-232, RS-485, analog outputs

- User-Friendly – No field calibration required

Optimize Your Extrusion Process

AST’s aluminum extrusion pyrometers help manufacturers improve:

- Extrusion speed

- Final product quality

- Energy efficiency

- Operational reliability

Installation of AST Pyrometers at Press Exit

Installation of AST Pyrometers for Billet temperature measurement

Looking for more industrial infrared pyrometers?

Explore our complete range of Aluminum Pyrometers for Extrusion, Casting, Rolling, Forging