Cement Kilns Temperature Control — Optimize Clinker Quality with Precise Infrared Pyrometer Sensing

Cement Kilns Temperature Control is critical for process stability and clinker quality—discover how advanced two-color infrared pyrometers enable real-time burning-zone monitoring, reduce unplanned shutdowns, and extend refractory life.

Table of Contents

Watch: How Pyrometers Transform Cement Kilns Temperature Control

In-Depth Breakdown: Key Insights Covered in the Video - Applications of Pyrometer & Camera in Cement Industry

- Kiln Burning Zone Application

- Kiln Inlet & Secondary and Tertiary Air

- Clinker Temperature Measurement

Kiln Burning Zone process, How it Works?

- The kiln is the heart of the plant, where most of the final chemical reactions take place. Kilns play a key role in ensuring the best quality clinker.

- There are many different types of refractory bricks and they have to withstand not only the high temperatures, but also the reactions with the meal and the gases in the kiln, abrasion and mechanical stresses caused by deformation of the kiln casing while rotating.

- The kiln temperature range is between 700ºC and 1800ºC. The combustion zone is in a more aggressive environment and therefore different parts of the kiln are coated with different types of immunity bricks.

- Severe changes in temperature can damage the resistant lining. The cost of refractories is a large expense in operating a cement plant, kiln stops are avoided as much as possible.

- Thus, accurate temperature monitoring plays a vital role in controlling the quality of the cement, avoiding stubborn failure and to maintain the energy efficiency of the kiln.

Infrared Pyrometers for Cement Kilns

Features

- wide band detector with spectral range from 0.7 to 1.15 μm

- It has real time color video for data monitoring

- Pyrometer offers RS 485 interface, Analog output 0..20mA & 4..20 mA

- Peak picker feature to measure accurate temp.

Benefits

- Faster & Accurate Temperature measurement

- Single unit with Display & electronics

- Protected with Sapphire Window

- 5 years Warranty

Precision Two Color Infrared Temperature Sensors A450 C+

Measuring temperature in this environment is difficult due to Dust & Smoke in the Field Of View, and elevated Ambient temperature at the installation Place. To overcome this difficulties we recommend Two color Pyrometer

Installation at-

Pyrometer installed by mounting a sighting tube on the kiln Door/Hood along with Water cooling assembly. Pyrometer Can be installed on the Kiln platform looking through the Observation Window. Where Additional Accessories of Cooling system not mandatory.

Clinker Cooler Process

- Clinkers are solid lumps of cement that leave the rotating kiln.

- The clinker is cooled in two places:

– In the kiln after the material passes through the combustion zone.

– In a clinker cooler after falling material from the kiln.

- A hot clinker is transferred to a mesh cooler, where it is cooled by air blowers.

- The cooled clinker is then removed using a conveyor belt to the mill.

- The hot clinker is rapidly cooled in air to achieve a high level of efficiency.

- It is very important to monitor the clinker temperature when looking for hot spots in the material at a temperature above a set threshold, and before it reaches the conveyor belt and causes damage.

Clinker Cooler Temperature- Pyrometer Solution

Temperature measurement of Clinker after cooler is important measure, because if the temperature exceeds above 200°C, it will burn conveyor and can cause a major shutdown.

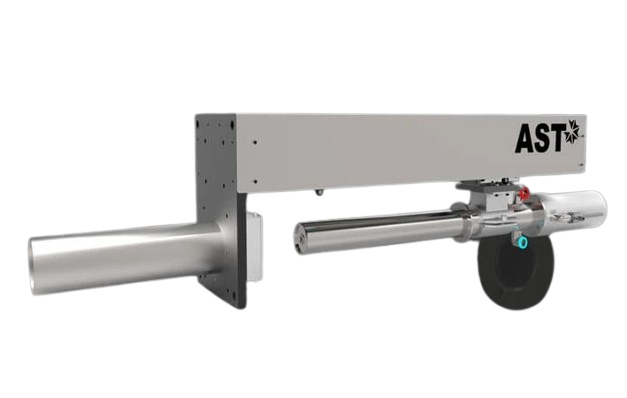

EL50

AL30

Pyrometer AST EL 50 or AST AL 30

Features:

- Sensor head withstands ambient temperature up to 120°C

- Inbuilt LCD Display and Keypad for parameterization

- Fast response time within milliseconds

- RS-232/RS-485 Serial interface card

installation:

- As per conveyor size and requirement.

PreCalciner Process

The raw materials are heated in the multi-stage arrange in cyclone pre-heater and then fed into a rotary kiln. Temperature is approx. 1400 Deg C Temperature Monitoring at every stage is critically important to ensure the Product quality, Kiln process efficiency and kiln life.

Recommended: AST A450 PL

Secondary & Tertiary Air process

Primary air: Blows the air by the burner, mainly to spray the coal powder. In addition- a combustion support function.

Secondary air: The hot air used to cool the clinker, cools the mesh directly into the kiln.

The direction of air flow is pre-cement kiln to tail cement kiln.

Tertiary air: Exhales the hot air used to cool the clinker into the kiln system, to the decomposing kiln to preheat the clinker.

Recommended : AST A 450C+

Furnace Camera In Cement Industry

The kiln and refrigeration burning area is the most important areas in the cement plant. Thus, monitoring of these areas is mandatory. The pyrometer in the combustion zone does not provide much information on the whole operation, but only a single measurement value from a small part of the kiln. If the target area is not adjusted the readings can be misleading. Rotary kiln is one of the most critical plant items in the cement production process. it is an essential requirement for operators to see the internal operations of the kiln on the screen in the control room, in order to detect ring accumulation, blockages or other disturbed conditions at an early stage.

KILN Burning Zone- Furnace Camera Solution by AST

Camera is the only solution for both Kiln & Cooler inside view. We have two types of camera:

Normal View & Thermal View Camera

Normal View Camera TFV 750 and TFV750/OV

Provide views of burner flames, material alignment and movement, and other process conditions in kiln and cooler, to plant engineers and operators in the control room. We use special color camera above 640 lines, pinhole lens and stainless steel came.

Explore our Furnace Monitoring Cameras

Furnace Camera Installation & View

Thermal View Camera TE 750 and TE 750/OV

To obtain more detailed process information about the kiln, we recommend using a short wavelength thermal view camera. Temperature monitoring across the manufacturing process is essential to support process efficiency and cement product quality.

It can also help to increase the life of the kiln through early detection of refractory issues or insufficiently quenched clinker, which could lead to production stoppages if left unchecked. Monitoring solutions also support safety and emissions control.

Schematic & Kiln View

- This camera is essential in the current situation, as the kiln rotates continuously and the clinker is collected on one side.

- This allows the thermal display camera to be installed under the burner towards the opposite side, and provides vision to the clinker and flame.

- The wide-angle image, with high spatial resolution, allows for accurate temperature measurements and important information about the process conditions within the fire area

- This camera is used in both the kiln burning area and the cooler area.

Installation

Thermal Camera In Cement Industry

Conveyor Temp Measurement: Thermal Camera Solution Coal Transportation Conveyor Monitoring

Ash produced by burning coal in power stations is used as a component in cement rotary kiln feeds. When coal is transported from Mines to the processing unit it also contains Hot inclusions. Due to this Coal can catch the fire & damage the Conveyor belt. Single point pyrometer can not able to cover the complete conveyor belt range hence not a suitable solution.

Thermal Imager can help to identify small Hot Spots on moving conveyors with covering the maximum area.

Installation: Top of the Conveyor belt

Temp. Measurement: Thermal Camera Solution Clinker Cooling Process

After leaving the Kiln, The Clinker reaches a temp. up to 1300 Deg C. it must be cooled down to 200 Deg C, in order to achieve a high degree of efficiency. Clinker cooling is necessary because hot clinker is difficult to convey. It will damage the conveyor belt and cause shutdown or production loss, repair & maintenance of the conveyor belt.

Hence we require a high-resolution Thermal Imaging camera to identify the small hot spot in the clinker to avoid further damages.

Installation: Top of the Conveyor belt

Conveyor Temp Measurement : Thermal Camera Solution

Clinker Cooler Monitoring & Coal Transport Conveyor Thermal Imager: LTE 80 Camera.

Features:

- Resolution : 80 x 80

- Works on LWIR ranges

- FOV : 27.5 degree X 27.5 degree

- Real-time display of thermal images

- High shock and vibration

- Tolerance for maintenance-free operation

Installation:

Top of the Conveyor belt

Lab Furnaces

Lab Furnace for Calibration of RTD/ Thermocouple

Lab Furnace : 1200L & 1500L

CALsys 1200L : 300 °C to 1200 °C

CALsys 1500L : 500 °C to 1500 °C

| Features | Calsys1200 | Calsys1500 |

|---|---|---|

| Accuracy | ±2 Deg | ±3 Deg |

| Resolution | 1 Deg | 1 Deg |

| Heating Time | 1.5 Hrs | 2.5 Hrs |

| Computer Interface | RS232 | RS232 |

| Stabilization Time | 15-20 Mins | 15-20 Mins |

Lab Furnace for Calibration of Pyrometer (Blackbody)

Lab furnace: 1200BB & 1500BB

CALsys 1200BB : 300 °C to 1200 °C

CALsys 1500BB : 500 °C to 1500 °C

| Features | Calsys1200 | Calsys1500 |

|---|---|---|

| Accuracy | ±2 Deg | ±3 Deg |

| Resolution | 1 Deg | 1 Deg |

| Cavity | Silicone Carbide | Silicone Carbide |

| Heating Time | 1.5 Hrs | 2 Hrs |

| Computer Interface | RS232 | RS232 |

| Stabilization Time | 15-20 Mins | 20 Mins |

Looking for more industrial infrared pyrometers?

Explore our complete range of Non-Contact Infrared Temperature Sensors for every application