In the Hot Rolling Process of Aluminum

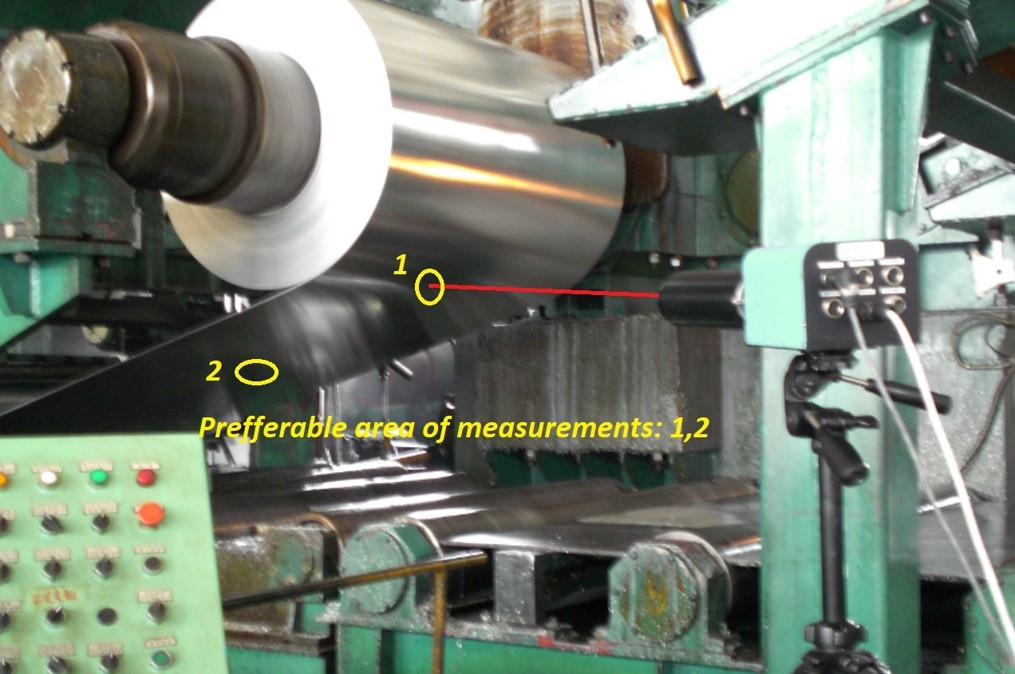

The first step for achieving good measurements is to avoid reflection phenomena; we recommend aiming the pyrometer at point 1 or 2.

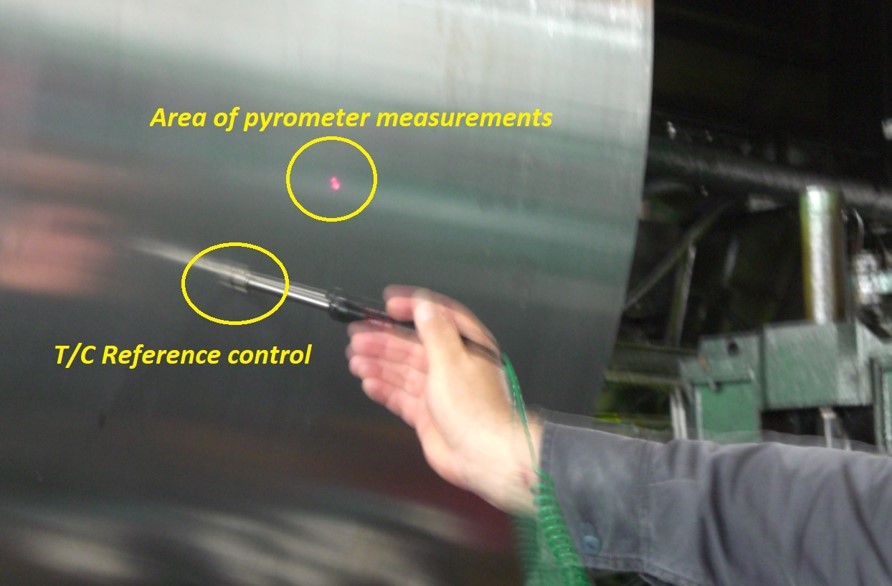

The marked yellow circles are samples of recommended locations for measurements.

The Pyrometer distance from the strip is flexible and thus is based on mounting convenience.

The strip is wide enough, so if we install the pyrometer, not at the pre-set distance, the measurement spot will become defocused (Larger). The only importance is that it will be inside the strip.

In most aluminum rolling processes, the spot size

(when it is still inside the target) doesn’t matter.

Yet, when there is a significant temperature gradient across the roll,it is recommended to have a big measurement spot.Thus it will measure all the areas covered by the measurement spot.

Usually, the Emissivity of a very bright aluminum strip surface can be even small than 0.04-0.05.

The minimal measured temperature will be much higher than the one mentioned for a black body with emissivity=1.

We designed the A5-EX pyrometer to measure above 105˚C. So as of the low emissivity, you will be able to measure only the highest range of strip temperatures, 240-340 ˚C.

Fine-tuning the temperature reading during the startup; “DX” parameter will be 1.025, and then adjust the “DY” parameter based on the actual strip temperature measured with a thermocouple.

The DY coefficient setting will differ for each alloy group (1 thousand; 3 thousand; 5 thousand; 8 thousand).

So, usually, we divide the pyrometer memory, and in each segment, we save different parameters.

During production, you don’t need to adjust the parameters;

You will only need to switch between memory segments accordingly to the production order.

During testing, you may switch the groups from the PC with our application software. But for everyday production use, we have many ways to change between memory segments.

Technical Solution Video