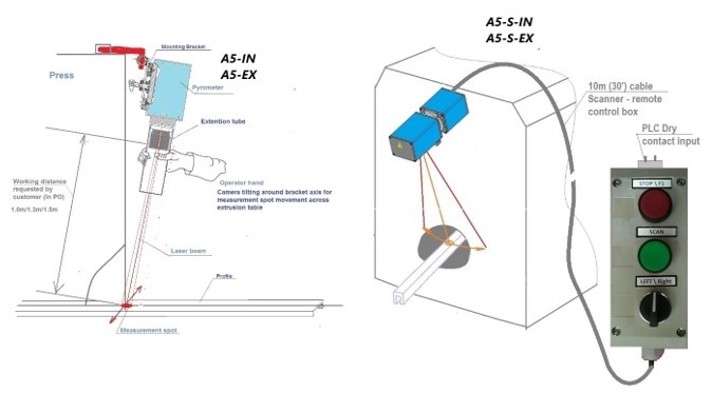

A5-S-IN A5-S-EX

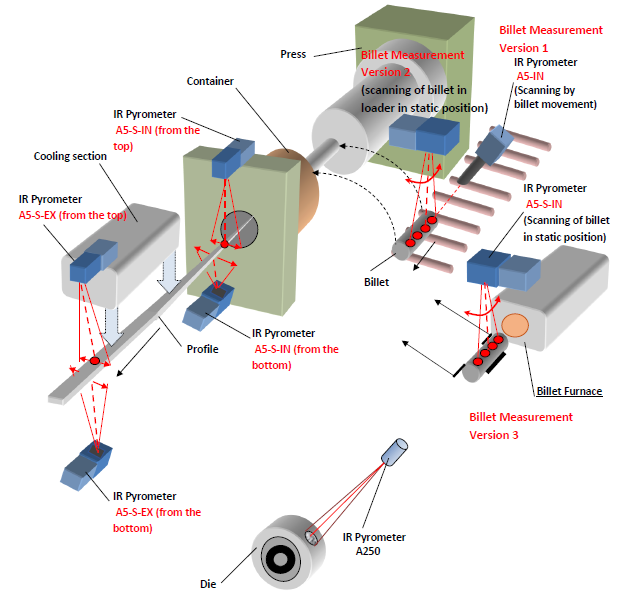

Temperature measurement in the extrusion process of aluminum, a variety of application options

An overview of the Aluminum extrusion line with a variety of options for measuring the temperature of the billets and profiles

∨ Measuring the billets with or without a scanner

∨ Measuring the Die with the A250 pyrometer

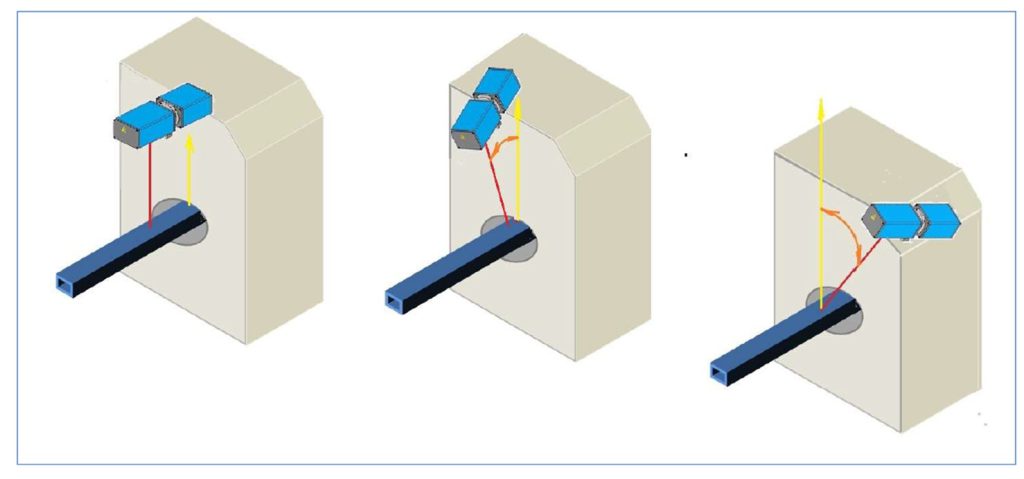

∨ Measure the profile at the die exit from above or below

∨ Measuring the profile in the cooling phase from above or below

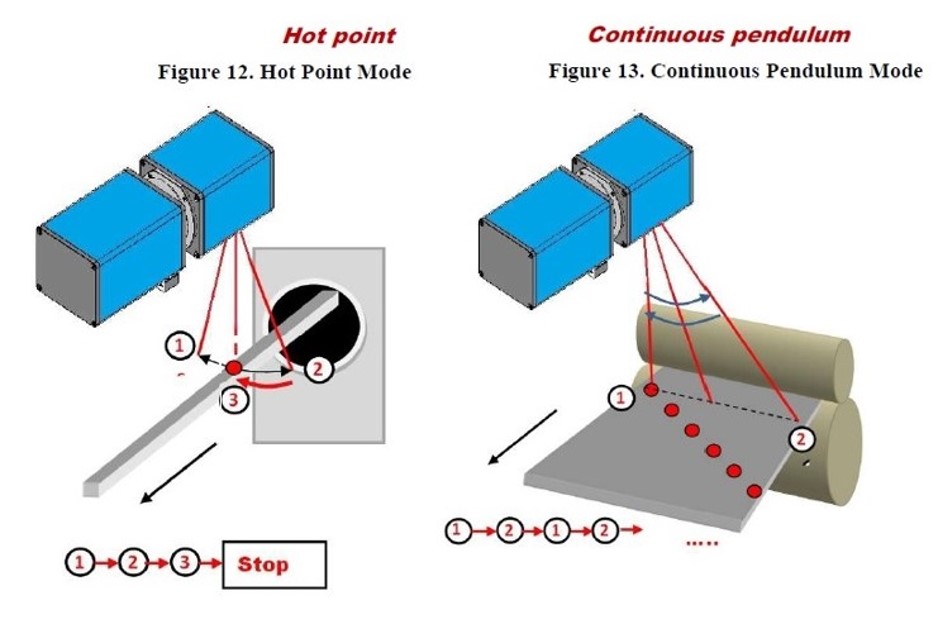

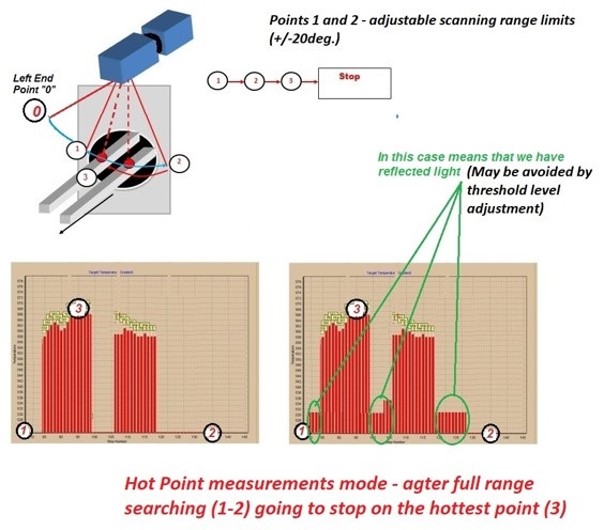

Four scanning options:

Single “Hot Point Mode” – The pyrometer will find the hot spot and stay there till the subsequent Activation

“Continuous pendulum Mode“ – The pyrometer scans continuously from one side to the other.

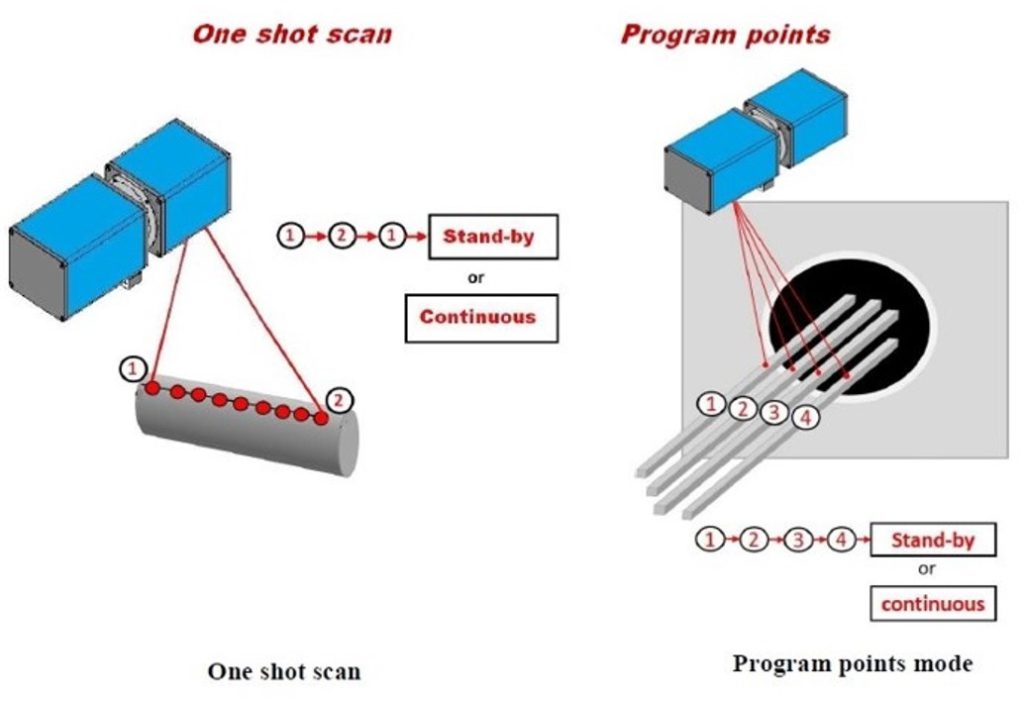

One shot scan-

Once activated, the pyrometer

will scan along the billet and return to the starting point.

Program point mode–

allows to set up to 20 points, where the scanner will move from one point to another and stop for a short time for measurements.

The Scanning mode can be

a single scan or continuous.

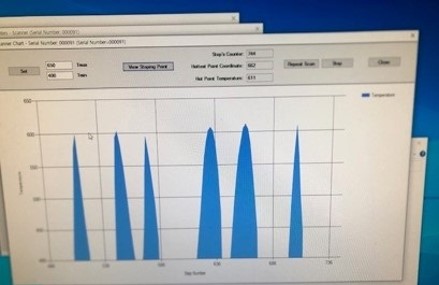

Example of the temperature distribution during scanning as recorded with AST NET Software

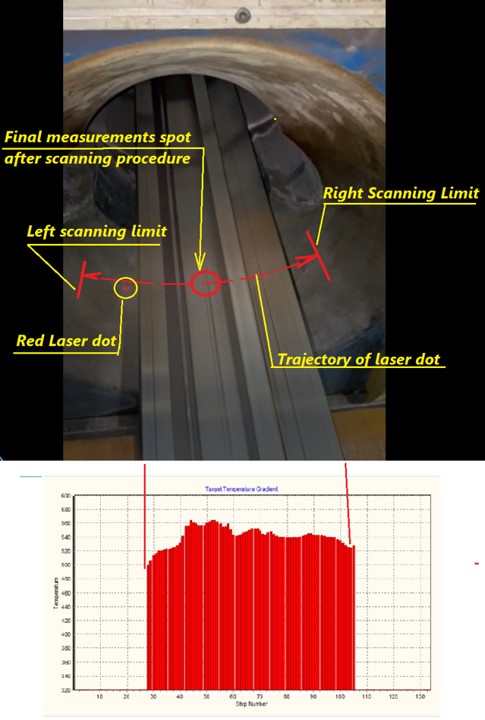

Temperature distribution diagram of aluminum profile as recorded on PC screen with AST NET

Safety is one of the advantages of pyrometer aiming with the scanner: in a manual aiming, the operator has to aim the pyrometer when he is in a dangerous area.

Scanning by a push of a button or automatically by extrusion press PLC.

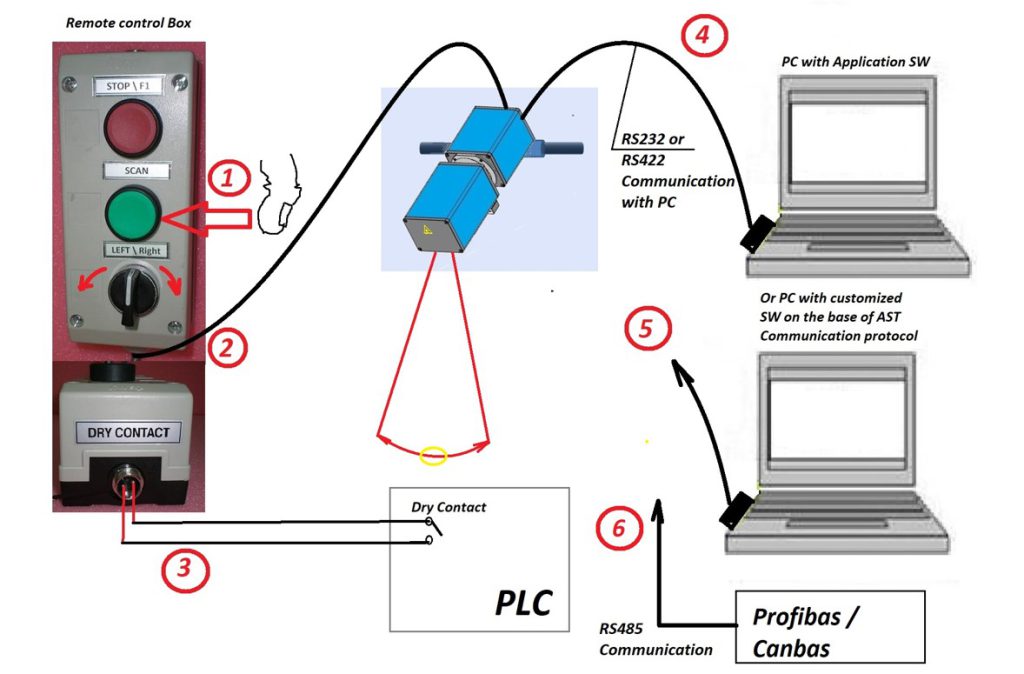

Scanner activation modes

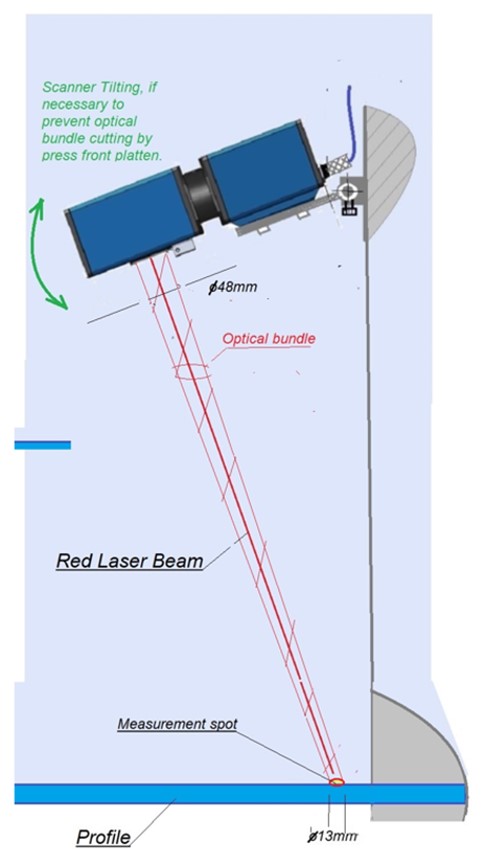

The scanner on the press:

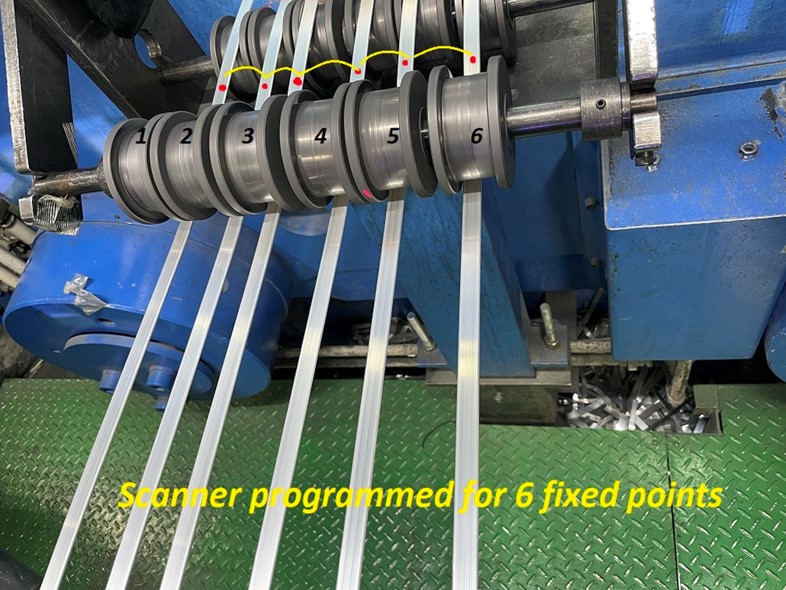

Extrusion of Multi-cavity aluminum profiles.

Scanner movement in “Program Points Mode” And PC picture of scanning results

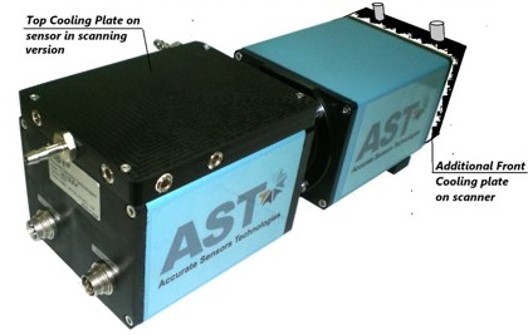

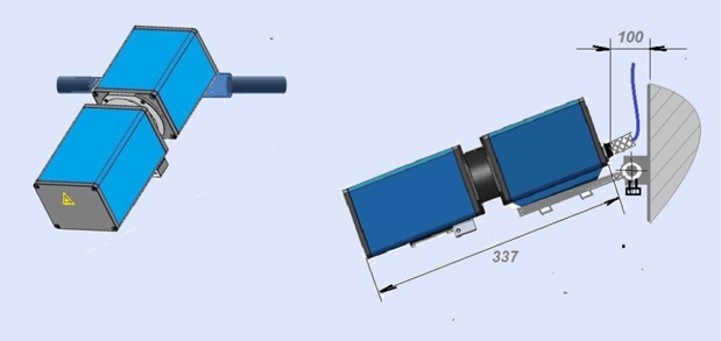

The Scanner with 2 Water Cooling Plates, Allows installation in a hot area up to 100 degrees.

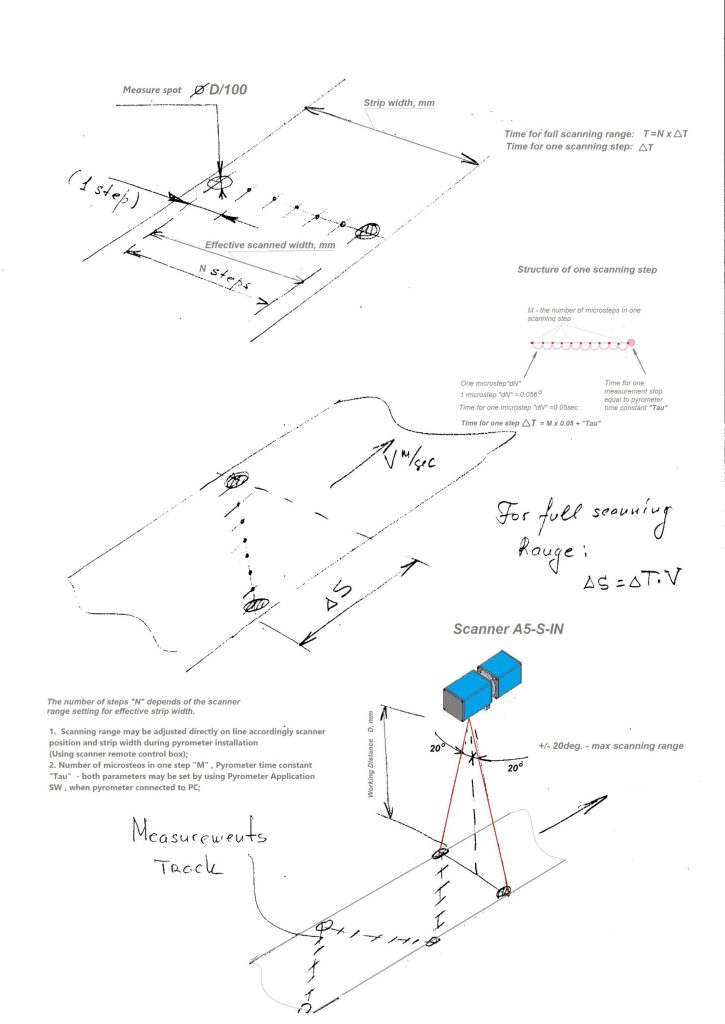

Scanner movements in

“Continuous Pendulum Mode”

for strip measurements

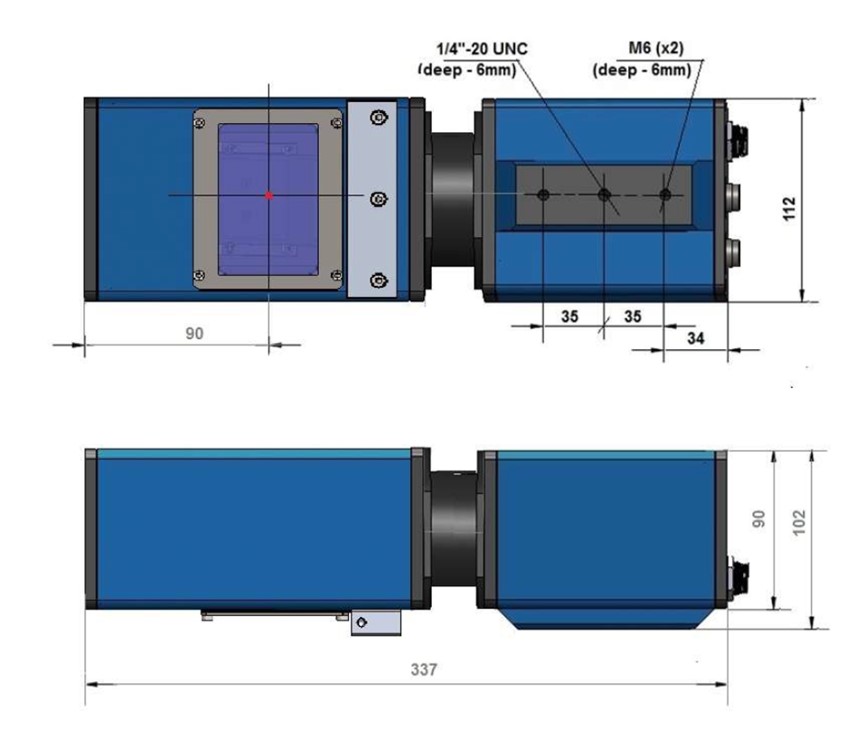

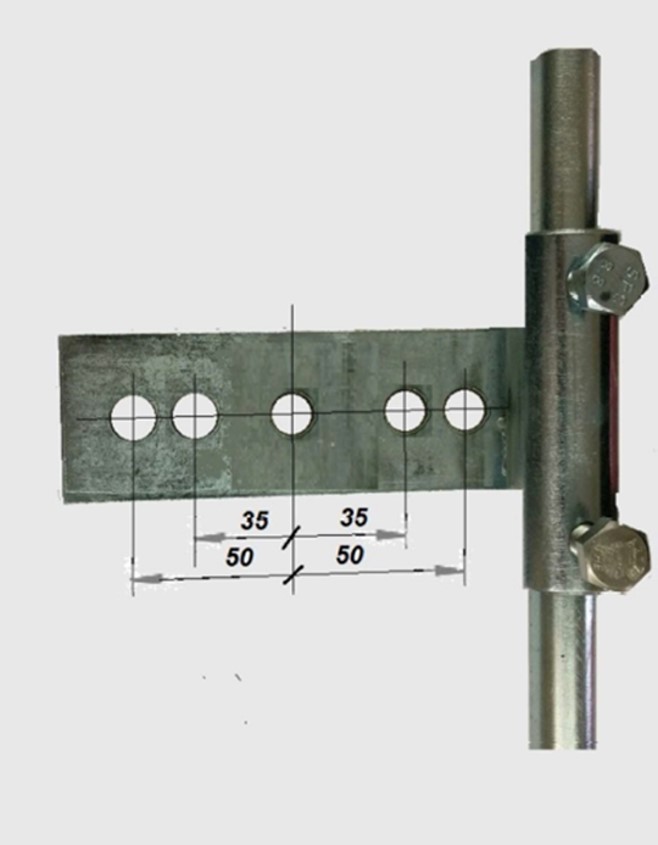

Scanner physical dimensions, Proposal for installation on a press

Flexible mounting on the extrusion press

Scanner Mounting Bracket

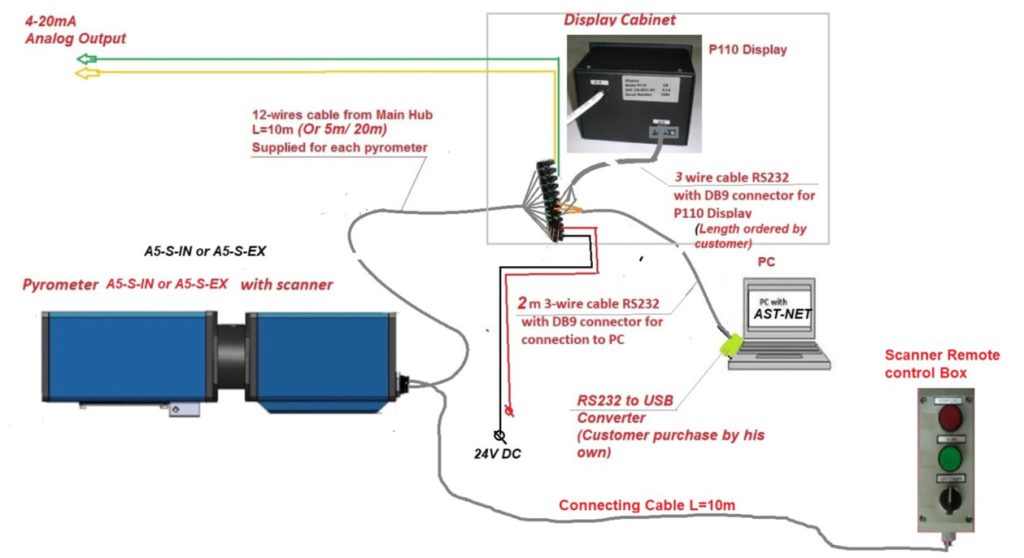

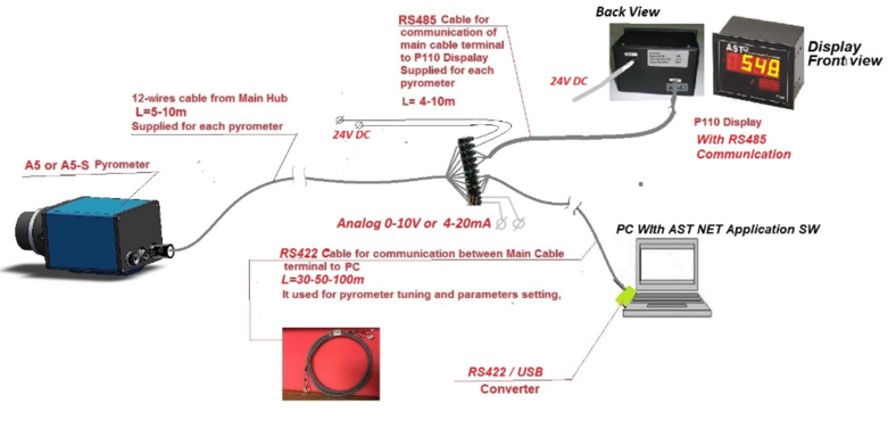

Communication options

Analog 4-20 miliAmp

Analog output 0-10Volt

Digital RS232

CanBus

Communication options

-Digital RS485

-Digital RS422

-USB

-Bluetooth

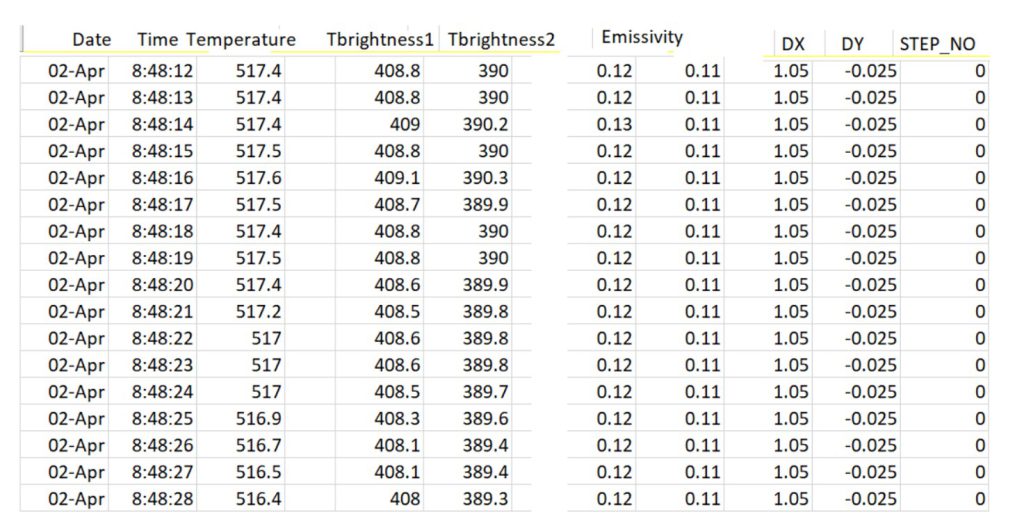

A data Logger, recorded during measurements by Application software and saved in EXCEL format.