Profile Measurement

Let’s address the issue of inaccurate temperature measurements at the exit of the press, using the pyrometer

A5-S-EX.

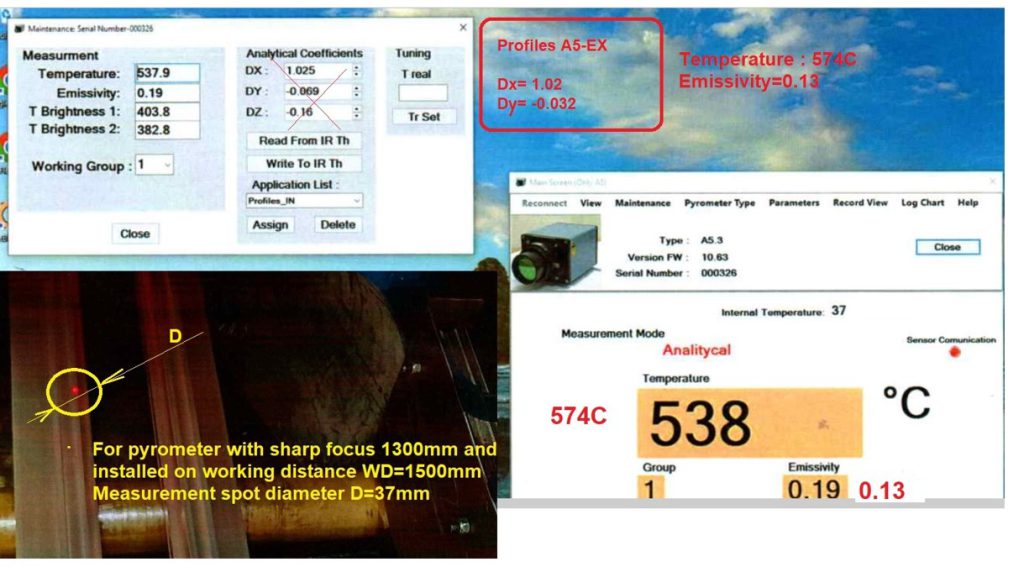

First, let’s double-check the coefficients for the A5-S-EX pyrometer for an aluminum profile as it struts its stuff out of the press. Dx=1.02 and Dy=-0.032 because math is our jam!

The upper right image displays the actual temperature values calculated with the correct initial coefficients. The real temperature is 574°C, and the emissivity value is 0.13.

A further step is to ensure that there are no stray lights that interfere with the measurement. The next step compares the measurement with a fast-response thermocouple to the pyrometer measurement.

When the correct DX and DY are used in the calculation, the measurement on the edge indicates a real temperature of 690°C with an emissivity of 0.05.

This value is influenced by external lighting conditions at the edge.

The pyrometer calculates the measuring temperature at the edges or sharp parts of the profile shape,

which is a common situation.

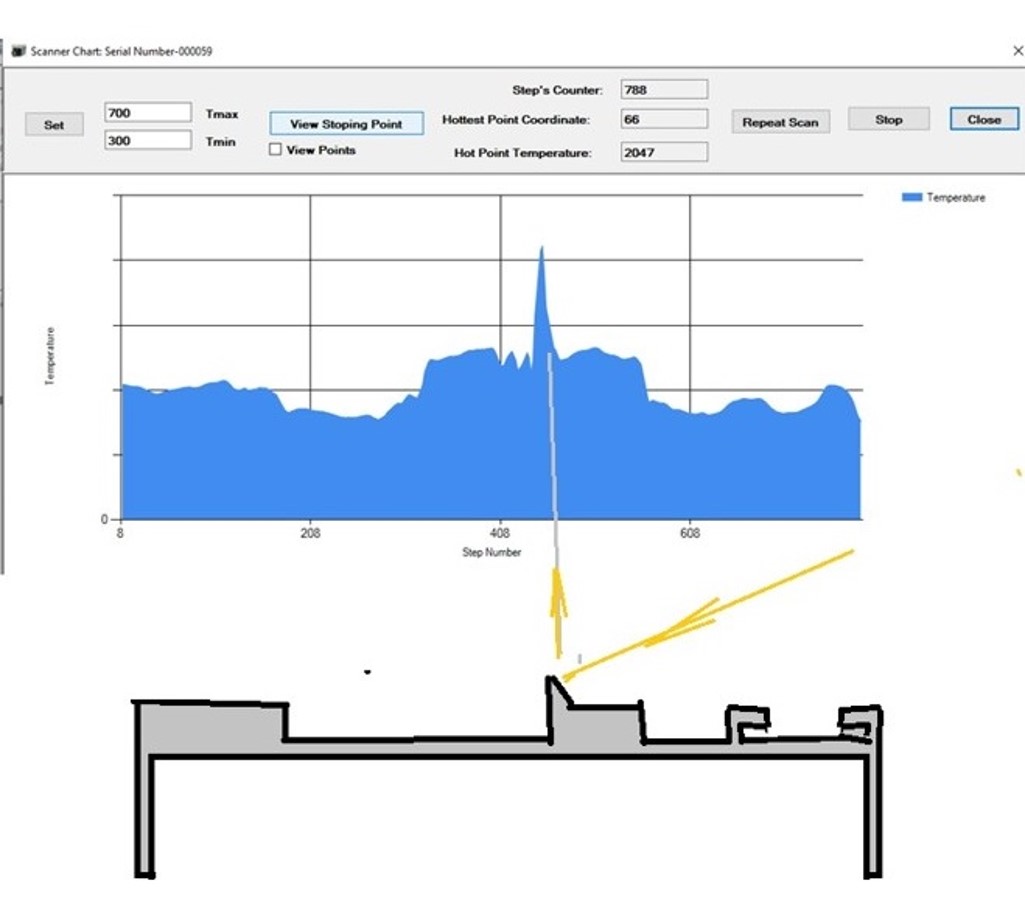

The scanner is programmed to stop at the hottest temperature points and occasionally halts at the edges.

Here are two images for reference.

The diagram illustrates that the sharp edge functions as a mirror, resulting in a noticeable peak on the temperature chart.

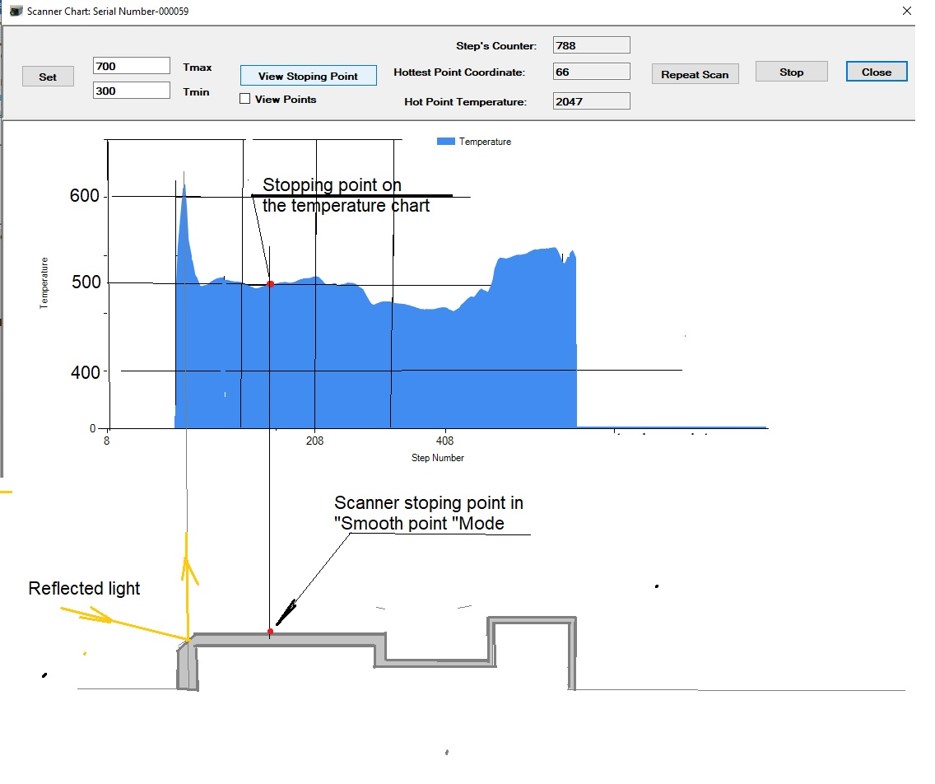

In the “Hot point Mode,” the scanner stops at the peak point; in the “Smooth point Mode,” the scanner will stop in the middle of the widest flat segment of a temperature across the profile.

(see the following picture)

In this smooth point mode, the profile edge acts as a mirror, but the scanner will halt at the point the red marker indicates. These are the accurate and intriguing temperature readings. We use the ‘Smooth Point’ mode for aluminum profiles unless there’s a specific customer request.

When the scanner stopped after scanning due to high reflection, it suggests that the scanner mode settings were modified or required adjustment.

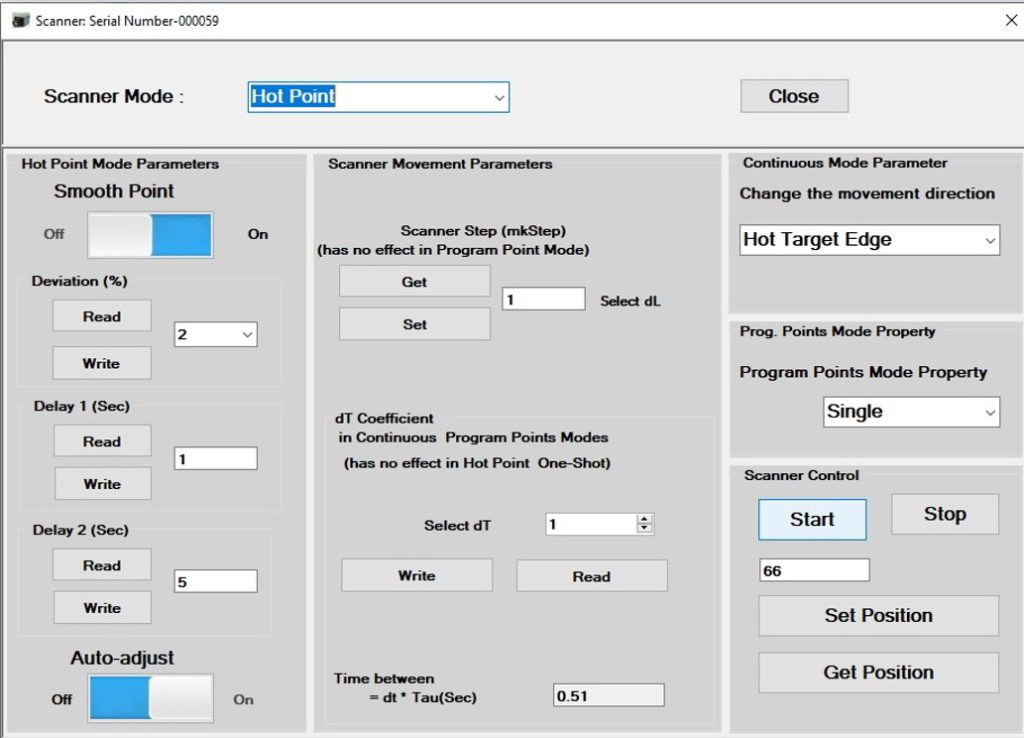

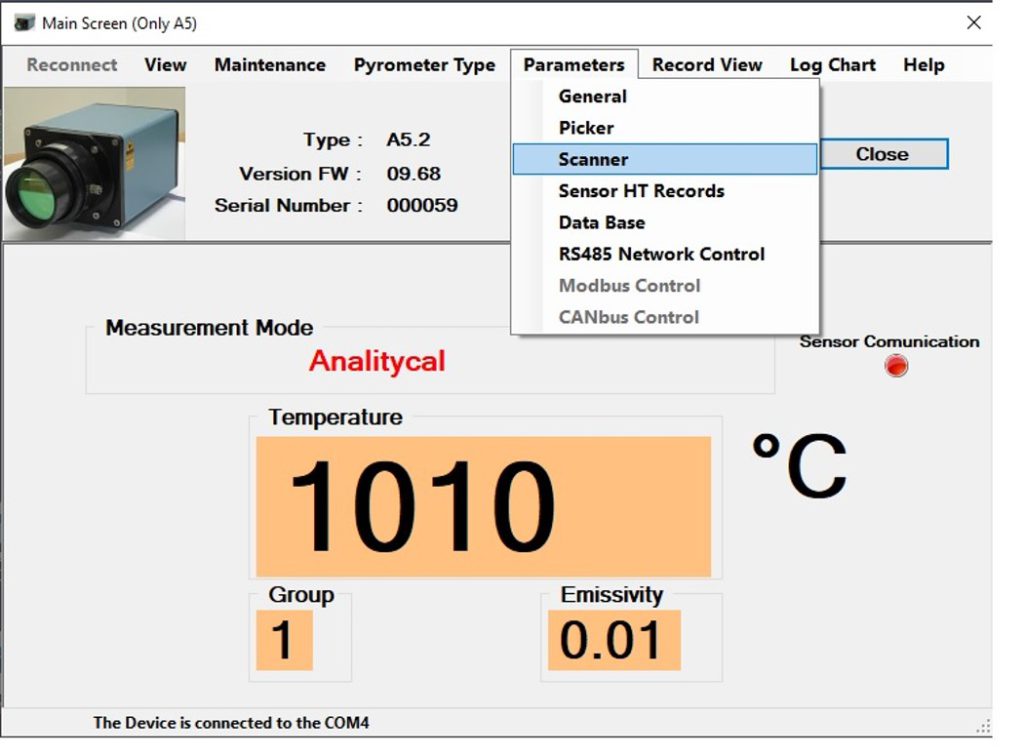

To verify this, we need to execute the AST NET software, navigate to the “parameters” section, and then access the “scanner” option. This will display a window containing the scanning parameters.

The scanner parameters have been configured with ‘Hot Point Mode’ and ‘Smooth Point’ enabled. As a result, the scanner will consistently stop within the normal zone of the profile without requiring external adjustments.

Video Technical solution