Billet Scanning

In this short Technical solution guide , we would like to share our experience in measuring the temperature of an aluminum billet.

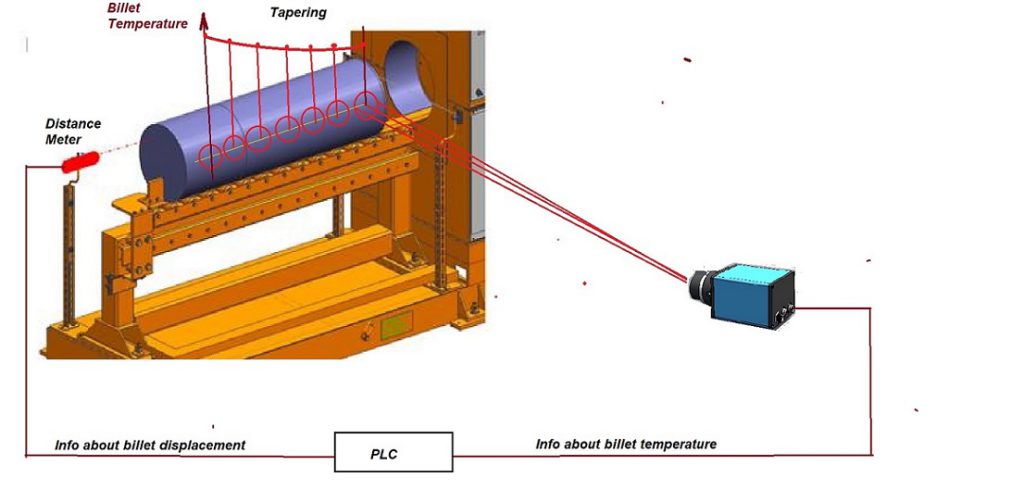

Two measurement options in this application:

-Measurement when the billet is in linear motion along its length.

-Measurement when the billet is static.

For measurements of a billet that has linear movement, we recommend using a camera without a scanner.

We recommend placing the pyrometer toward the furnace exit and at any intermediate point between the furnace exit and the container, or even when the billet is pushed into the container by the dummy block.

Measuring the temperature while the billet is pushed to the container is recommended for the aluminum 1000 series; this alloy has high thermal conductivity, and the temperature may significantly change during a few 30-40 sec between furnace to loading.

When measuring the aluminum billet temperature is required while the billet is not in motion, the recommended solution is an A5-S-IN type scanner or A5-S-EX.

Our scanner has several operating modes.

“One Shot Mode” in this mode, the billet is scanned on continuous movement, and the Information about the current scanner position and the temperature can be received digitally.

Program points mode

During the scanner installation setup, the customer will fix the position of the points where the scanner will stop for a specific time during its movement.

Choosing the scanner installation location will be done while considering the maximum angle at which the scanner scans and the size of the desired measurement point.

The outcome scanning angle is a result of simple trigonometry, depending on working distance and billet length.

The angular scanner step is 0.05 dgree. The time of One Step is 0.010 second.

For example:

If the working distance (WD)=2000mm, and billet length L=1000mm, 560 continuous steps will take about 5.6 second.

If we choose to add 3 Stops

of 0.5 second each –

The total time will be 7.1 second.

For a camera without a scanner, measurement time will depend on billet speed, and the pyrometer will transmit a measurement every 100 milliseconds.

Technical solution Video