Continuous Casting

Wire Production

Identify optimal temperature control points for continuous Properzi machine during aluminum rod production.

Continuous Properzi line for aluminum slabs-

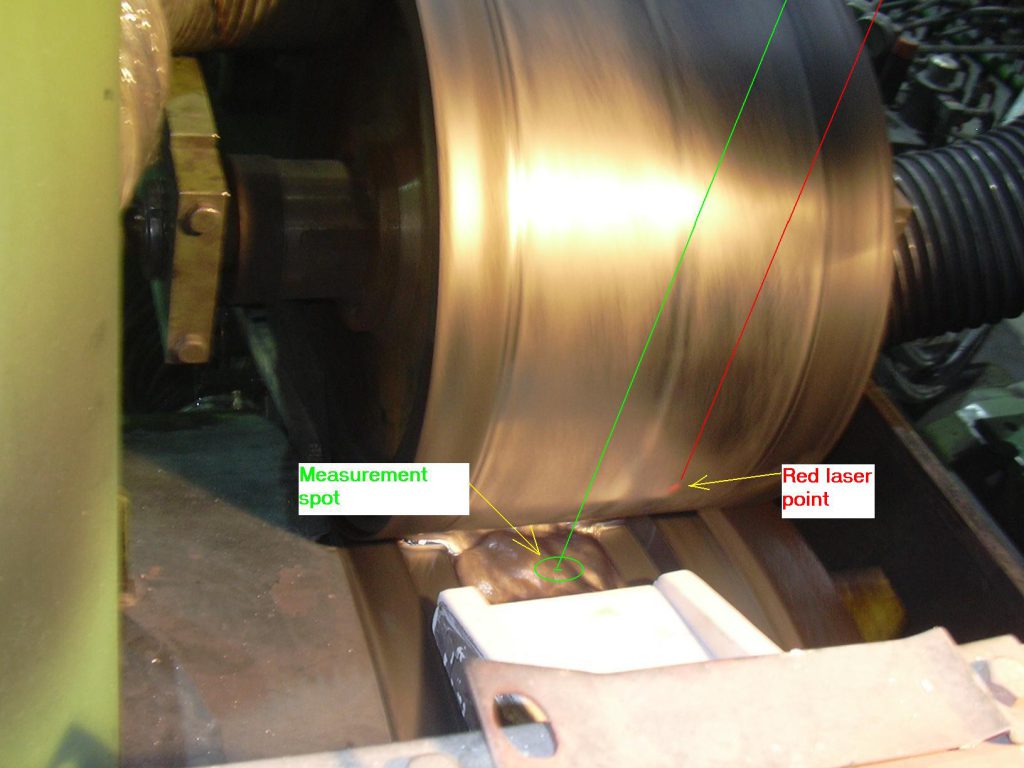

How to correctly install the AST A5-IN thermometer for bar temperature measurements?

On-site installation

From The Top

From The Side

Continuous casting machine

Continuous casting data logging

Properzi line, ALUAR, Argentina

Continuous casting data logging

Properzi line, ALUAR, Argentina, AL 1000

Continuous casting data logging

Properzi line, ALCAN Cable, Canada, AL 16160

Taking temperature measurements on the rod coiler.

Continuous Casting

Strip Production

Methods for measuring temperature on a wide strip caster

We conducted a temperature profile measurement, using a scanner along a strip.

Scanning track during wide strip casting process

Measurements on narrow strip caster

Strip Caster and liquid aluminum - temperature measurements

Temperature measurements of liquid aluminum stream.

Recording the surface temperature of a liquid aluminum bath.

Recording the temperature of a liquid aluminum stream.

Recording the surface temperature of a liquid aluminum bath.

Recording the temperature of a liquid aluminum stream.

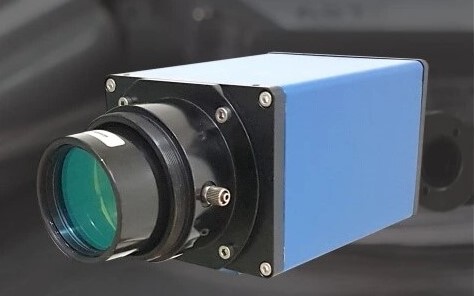

The A5-IN – IR Thermometer, is designed for continuous temperature measurements of casted bars and strips.

Features:

- Simple to use - no calibrations required

- List Item #High accuracy - (1%) in real site conditions

- Capable of measuring targets with variable emissivity

- Measures through smoke, dust, water vapor, etc.

- Temperature range: 350-1000°C

- Rugged design

- Full range of accessories

- Wide range of built-in functions

- Application: Aluminum forging, continuous casting, rolling.

Optional:

- Display P110 monochrome single channel

- Pointing laser source: Class II

Ambient Condition:

- Operating temperature range: 0°C +50°C

- Storage temperature range: -20°C +70°C

- Humidity: unlimited for the sensor-head

Performance:

- Temperature range : 350-1000°C

- Emissivity range: 0.1 - 1.0

- Response time: 0.1 - 10 Sec

- Default value: 0.5 sec

- Accuracy and Repeatability: +-1%

Electrical Specifications:

- Power supply: 24VDC 0.25 - 0.15 A

- Optional outputs: 4-20 mA, 0-20 mA,

- 0-10 V, RS-232, RS-422, RS485, Modbus, OpenBus, Profibus.

Mechanical Specifications:

- Sensor overall dimensions: 215 x 110 x 105.0 mm

- Sensor weight: ~2.0 kg

Optics:

- Spot diameter: 10mm from a distance of 1 meter

- Different optics is available.

A5-S-IN \ A5-S-EX scanning system

Features:

- Plug & Play, simple to install

- Fully automatic tracking

- Manual option of camera aiming

- Allows for continuous reliable temperature measurement

- Selection of scanning modes

- Hottest point

- Smooth point

- Program point (pendulum mode)

- Continuous scanning (pendulum mode) Adjustable scanning range up to ± 22º

- Adjustable scanning step from 0.1º to 5º

- Adjustable scanning time

- Minimal working distance 1 meter

- Maximal working distance target size dependence

Metal Processing Application:

- Profile, Billet, Strip and bar.

Alloy Selector AS3000

This device allows switching groups manually, by using its thumbwheel switches and push button. It is connected to P110 display with using of special cable.

Below the picture 1 of the device is shown:

Alloy Selector AS3000