Using a Pyrometer

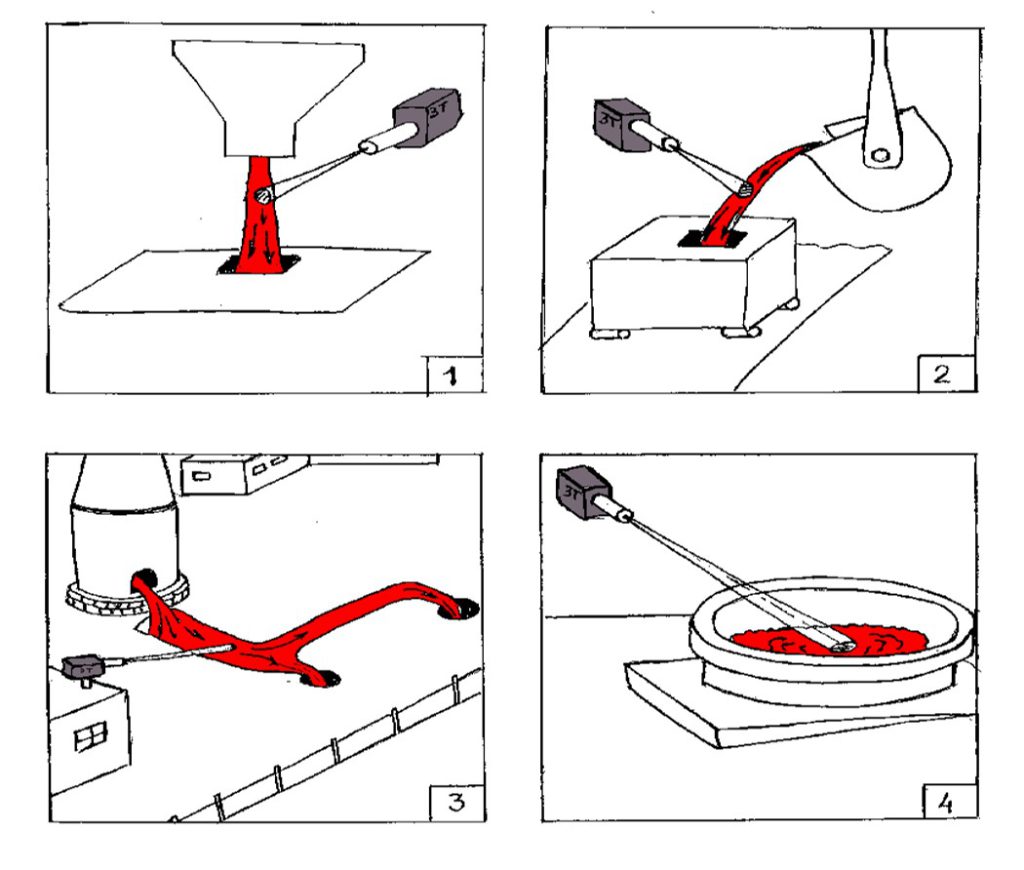

Iron and Steel Casting

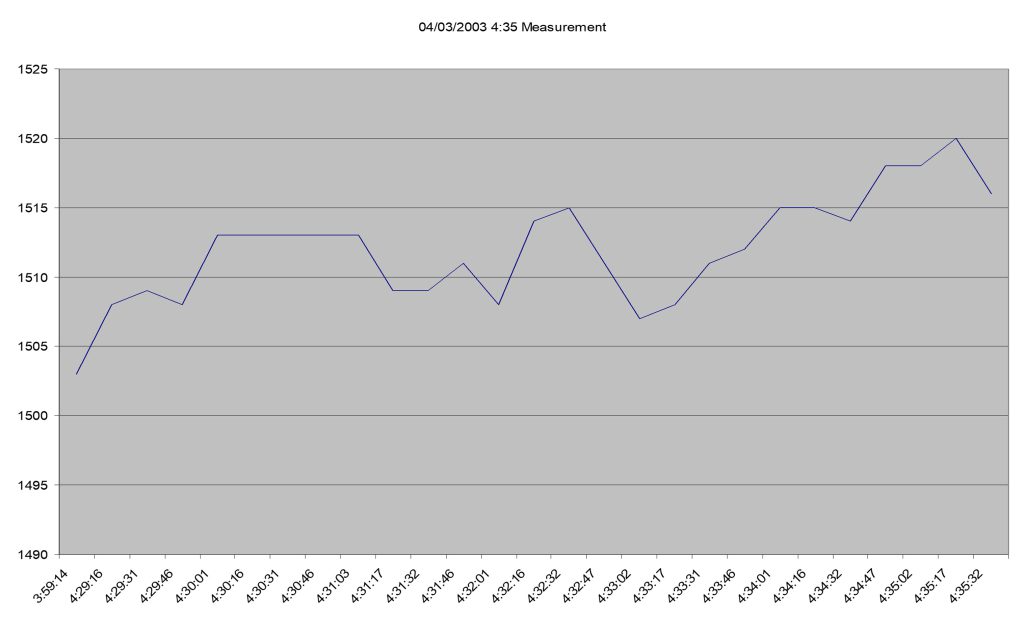

Liquid grey iron at the exit of the blast furnace (Kobe-steel Japan)

Liquid grey iron at the exit of the blast furnace (Kobe-steel Japan)

Liquid grey iron- Blast furnace exit (Kobe-steel, Japan)

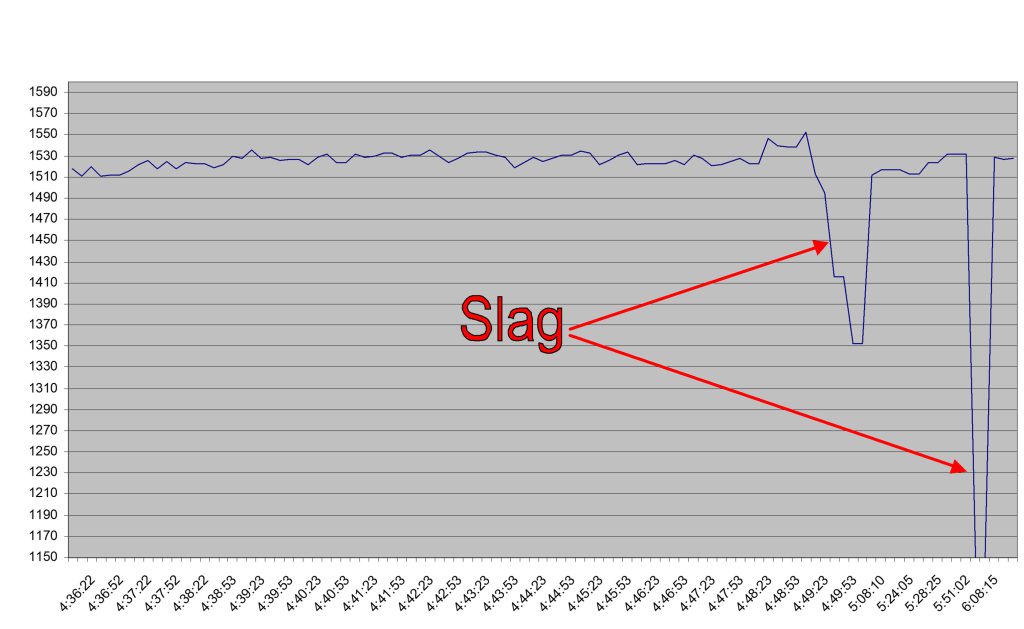

Slag and dross on the liquid metal surface

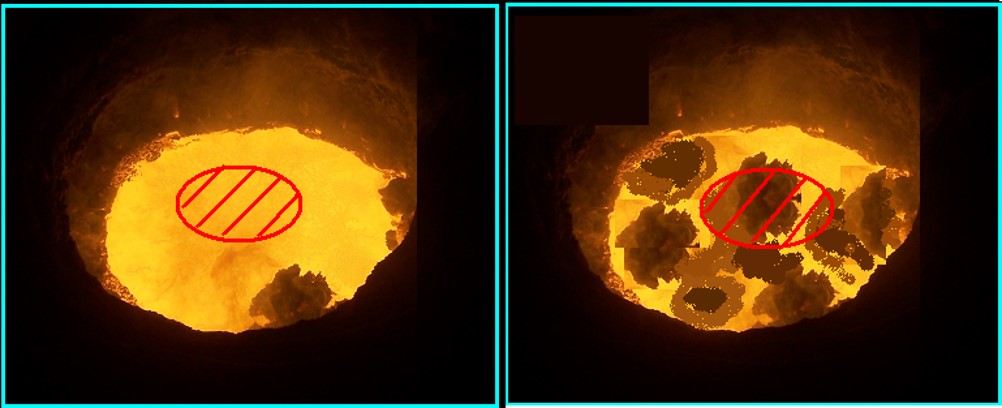

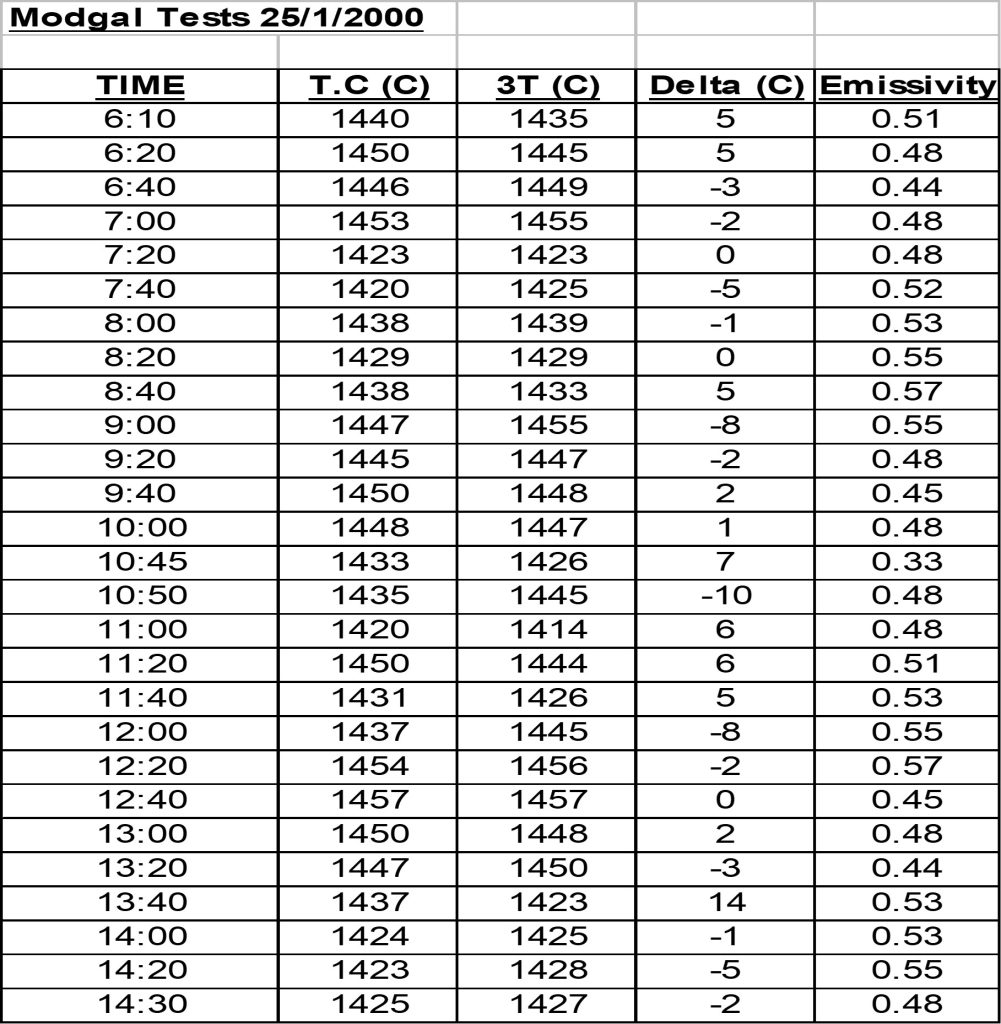

Spheroidal and non-spheroidal gray iron casting

( Modgal, Israel)

Spheroidal and non-spheroidal gray iron (Modgal, Israel)

Spheroidal and non-spheroidal gray iron casting (Turkey)

Spheroidal and non-spheroidal gray iron (Turkey)

A5-1W-PL / A5-1W-TL: 105 to 3000°C (221 to 5432°F)

A5-1W-FO: 300 to 1500°C (572 to 2732°F)

A5-1W-PL

A5-1W-FO

A5-1W-TL

AST A5-1W Infrared Pyrometer is specially designed for non-contact temperature measurement of non-gray bodies found in many applications like metal processing, heating, silicon, and ceramics.

AST A5-1W-PL, A5-1W-TL, and AST A5-1W-FO are One-wavelength pyrometers that use application-specific databases derived from years of experience in a real application.

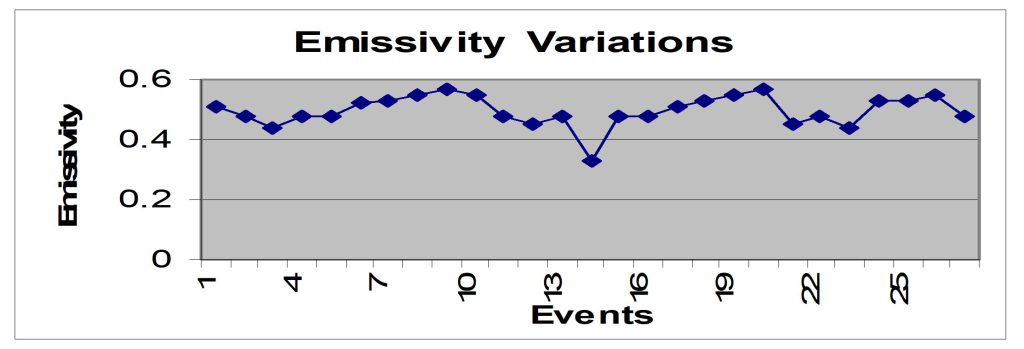

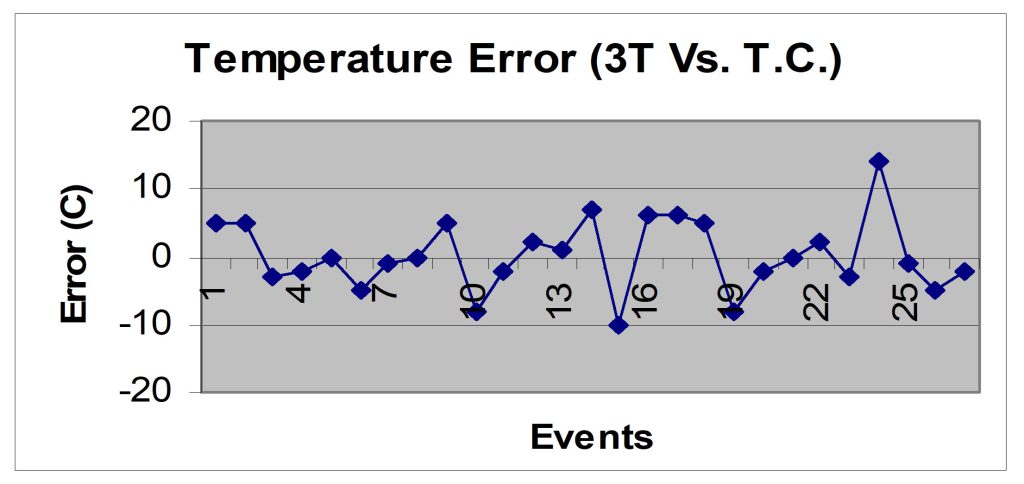

Our pyrometers use special algorithms to accurately calculate both the actual temperature and emissivity of the surface Online. They have a laser pointer aligned in line with the detector to ensure both laser and detector are aimed in the same spot. This helps precise aiming even in long distances.

Features

- ∨ High accuracy – 0.25% ±2˚C (3.6˚F) of measured value for a full range of emissivity.

- ∨ High consistency, suitable for closed-loop control.

- ∨ Temperature ranges – see table at the beginning of next page.

- ∨ Temperature range for measurement in front of a blackbody, when measuring a shiny body minimum temperature will be higher.

- ∨ Fast response, compared to T/C.

- ∨ Durability, low maintenance.

- ∨ Full range of accessories and wide range of built-in functions.

- ∨ Easy to install in the existing line, replacing of contact probes.

- ∨ Capable of measuring targets with variable emissivity.

- ∨ AST NET SW software for PC.

- ∨ AST Pyrometer Android Application via Bluetooth.

Optional

- ∨ Mechanical and Electrical Accessories

- ∨ RS422, RS485, OpenBus, USB, Bluetooth, Alarm

- ∨ Special filter for High power plasma

Standard Scope of Supply

- ∨ Integrated laser pilot light – Models A5-1W-PL and A5-1W-FO

- ∨ Built-in telescope aiming – Model A5-1W-TL

- ∨ Digital Interface RS-232

- ∨ Calibration Certificate, PC Software & Operation Manual

Applications

- ∨ Steel annealing line, Tube, hot-dip line

- ∨ Copper – rod, bars, and strip

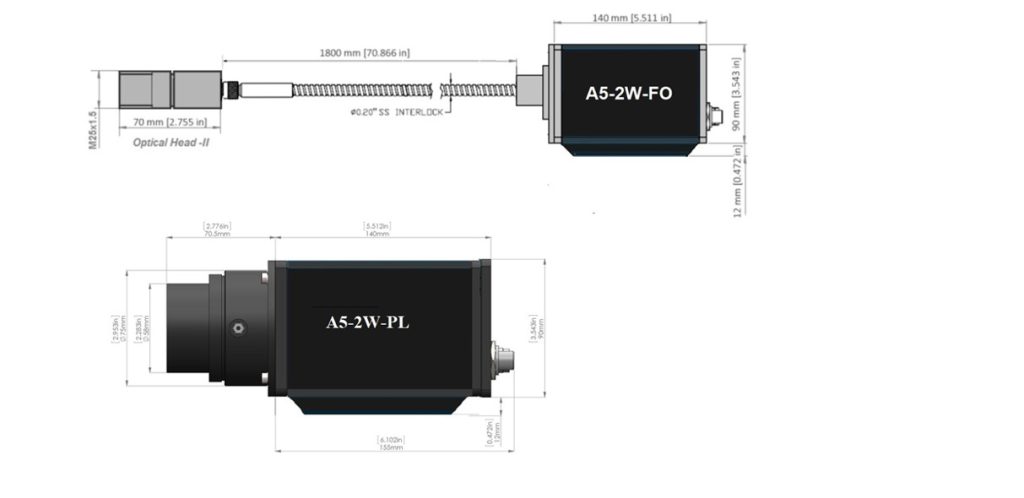

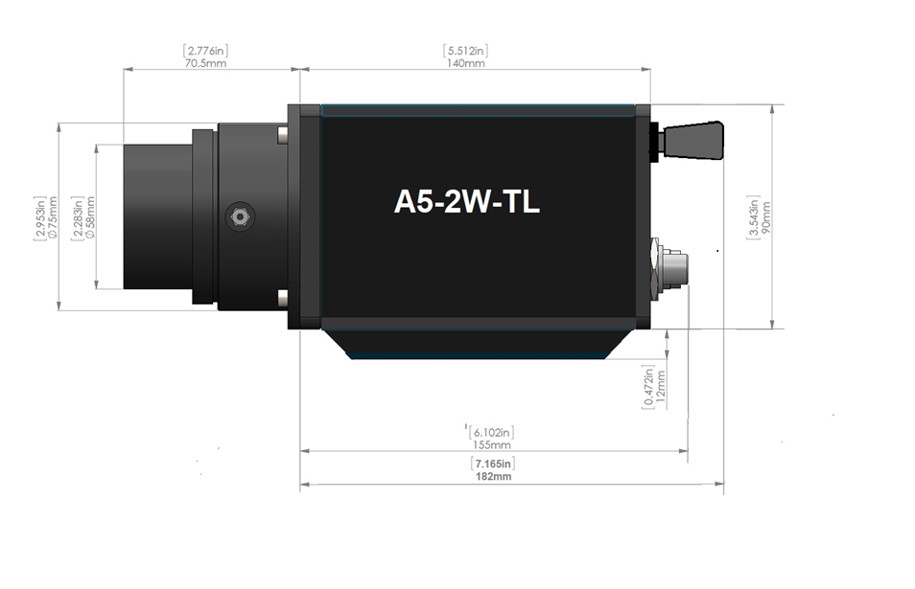

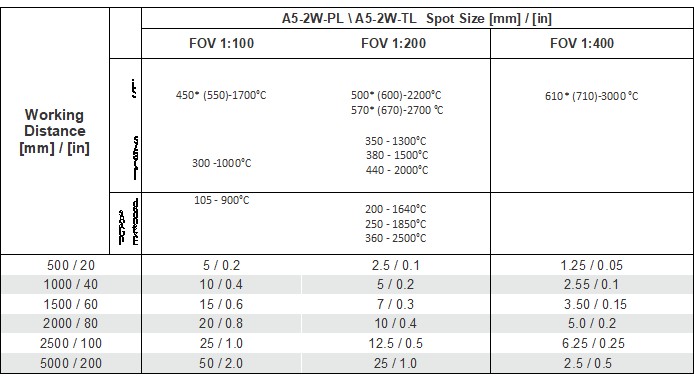

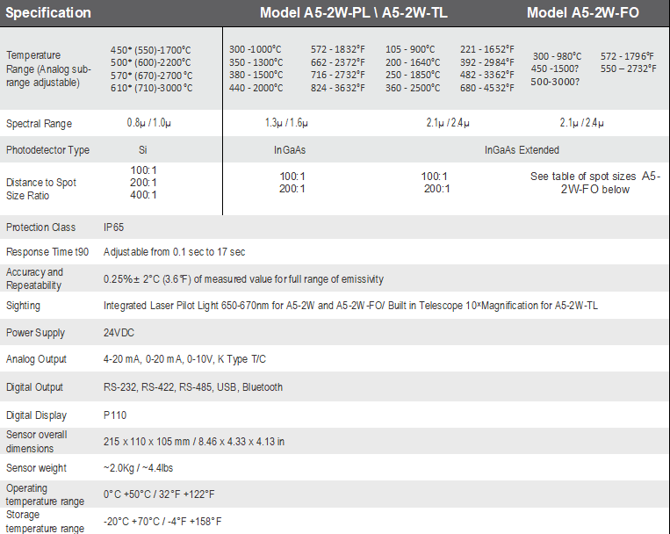

A5-2W-PL / A5-2W-TL: 105 to 3000°C (221 to 5432°F)

A5-2W-FO: 300 to 1500°C (572 to 2732°F)

A5-2W-PL

A5-2W-FO

A5-2W-TL

Features

- ∨ High accuracy – 0.25% ±2˚C (3.6˚F) of measured value for a full range of emissivity.

- ∨ High consistency, suitable for closed-loop control.

- ∨ Temperature ranges – see table at the beginning of next page.

- ∨ Temperature range for measurement in front of a blackbody, when measuring a shiny body minimum temperature will be higher.

- ∨ Fast response, compared to T/C.

- Bluetooth.

- ∨ Full range of accessories and wide range of built-in functions.

- ∨ Durability, low maintenance.

- ∨ Easy to install in the existing line, replacing of contact probes.

- ∨ Capable of measuring targets with variable emissivity.

- ∨ AST NET SW software for PC.

- ∨ AST Pyrometer Android Application via

Standard Scope of Supply

- ∨ Integrated laser pilot light – Models A5-2W-PL and A5-2W-FO

- ∨ Built-in telescope aiming – Model A5-2W-TL

- ∨ Digital Interface RS-232

- ∨ Calibration Certificate, PC Software & Operation Manual

Optional

- ∨ Mechanical and Electrical Accessories

- ∨ RS422, RS485, OpenBus, USB, Bluetooth, Alarm

- ∨ Special filter for High power plasma

- ∨ Manual

Applications

- ∨ Diamond Growing, wafer Annealing – CVD Crystal Growing

- ∨ Steel annealing line, Tube, hot-dip line,

- ∨ Copper – rod, bars, and strip

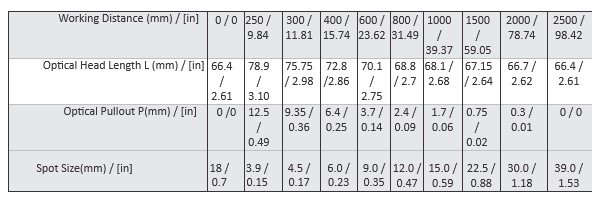

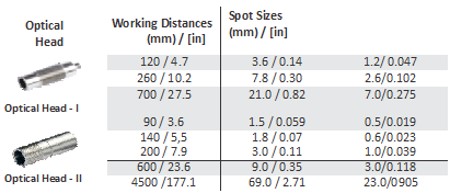

Spot sizes for A5-2W-PL/A5-2W-TL (Range 2/0-2/5 mkm/ InGaAs Extended)

Spot Sizes for A5-2W-FO

(Range 2/0-2/5 mkm/ InGaAs Extended)

Technical Specifications

* Tmin in Single Wavelength Mode only for λ2= 1.0μ. In Dual wavelength mode Tmin value is 100˚C higher.

AS3000 Application Selector (Reference no: 300-07)

Power Supply Unit

(Reference no: 200-09)

Air Purge Tube 200 mm

(Reference no: 200-03)

Display

(Reference no: P-110)

Adjustable Mounting

(Reference no: 200-01)

Air Purge Tube Adapter

(Reference no: 200-02)

Frontal Water-Cooling Plate (Reference no: 200-06)

Top Water-Cooling Plate

(Reference no: 200-10)

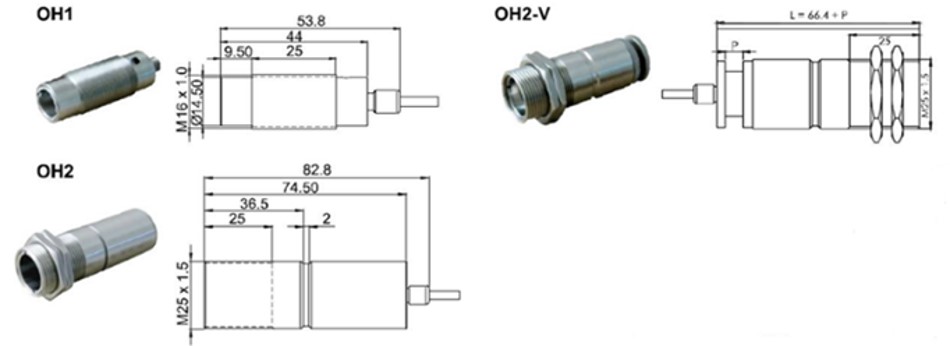

Air purge unit for optical head II (Reference No. 8200-01)

Air purge unit

for optical head I

(Reference No. 8200-02)

Adjustable Mounting

for optical head II

(Reference No. 8200-03)

Adjustable Mounting

for optical head I

(Reference No. 8200-04)