Boris Shtarker

Senior physics and optics engineer

Application: Quartz Fusing using Infrared Non Contact Pyrometer AST AL514

chemical composition of quartz and silica glass is similar. Both consist of Silicon Dioxide but there exists a significant difference among their structural composition. Silica glass commonly known as glass is amorphous while quartz is crystalline in nature. This change in the structural composition is responsible for the change in the properties of these materials as well. The fusing process of the quartz is different from fusing process of glass. It has high melting point like a metal. It does not have a distinct melting point as crystalline materials, but softens over a fairly broad temperature range. This transition from a solid to a plastic-like behavior, called the transformation range, is distinguished by a continuous change in viscosity with temperature.

Role of temperature:

The flame temperature plays a crucial role during the quartz tube fusing process. The right hot flame is essential for maintaining the right process temperature. Wrong flame temperature like heating for longer duration or too much heating leads to the formation of bubbles in the melted region. The failure in the joint is also a result of the contamination caused during flame heating. Oxy hydrogen flame is mostly used in this process as it is useful in achieving the right temperature and provides clean flame region for the fusing process. As Quartz is crystalline entry of foreign element in the matrix can easily cause dislocations near the crystal boundaries. The clean flame of hydrogen is useful as compared to the contaminated flame containing loose Carbon ions. The carbon ions can mix with the matrix and may cause contamination.

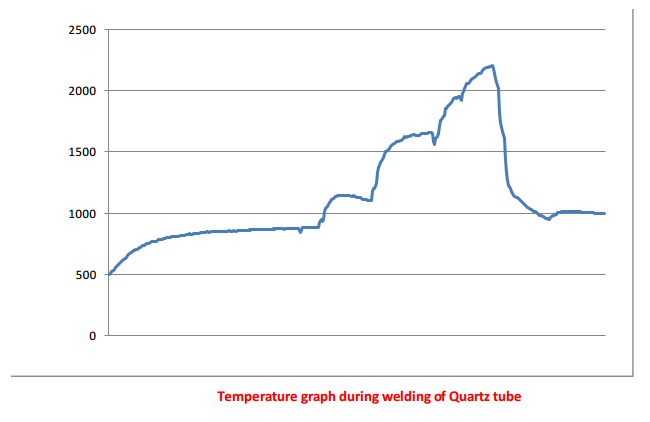

In quartz tube fusing application, the temperature rises above 2000°C. Using infrared pyrometers temperature of both the surface and depth of quartz tube can be measured. Since in this application the surface temperature of the tube is important, a pyrometer working at 5.14um is recommended. Quartz tube with 2mm wall thickness is opaque at 5.14um wavelength. Also this wavelength makes no effect of O2-H2 flame. Since glass is a poor conductor of heat, and can change surface temperature rapidly; the pyrometer should have a short response time.

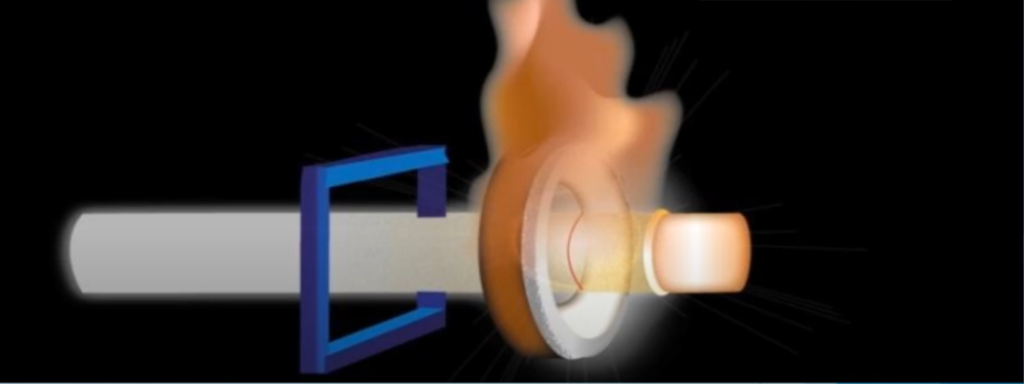

The below figure shows the quartz fusing application.

Solution to the Application

We offer AST AL514 model for this application. This pyrometer provides the advantage of noncontact temperature measurement of glass surfaces and quartz surfaces. The AST AL514 pyrometer is used for target temperature ranging from 400°C to 2500°C. The electronic assembly is protected by IP65 rugged stainless steel housing.

AST AL514 has a fast response time of 20msec. AST AL514 is supplied with laser targeting light or through the lens sighting for precise targeting. It has USB output and “infrasoft” PC software for data logging and remote parameter setting. When connected to PC using USB port, pyrometer works stand alone without any external power supply.

Pyrometer has user selectable analog output 0/4…20mA, 0…10V and digital output RS 232 and RS 485.